When specifying an overhead crane for a given application, a number of factors must be considered. One of the most critical is duty cycle, determined based on anticipated frequency of use, type of load and the average weight of the handled loads. That’s because, if the selected crane is not properly specified for these conditions, the components will not be engineered to match the actual application. In turn, the crane will likely wear faster, negatively impacting the longevity and life of the equipment. For this reason, it’s critical to select the right crane with the correct duty classification — and follow the manufacturer’s recommended maintenance program — to ensure the full return on the investment.

The Crane Manufacturers Association of America (CMAA), offers universally accepted guidelines for design and construction between the manufacturer and purchaser of cranes and hoists, including how to determine duty cycle. This important calculation in two CMAA specifications:

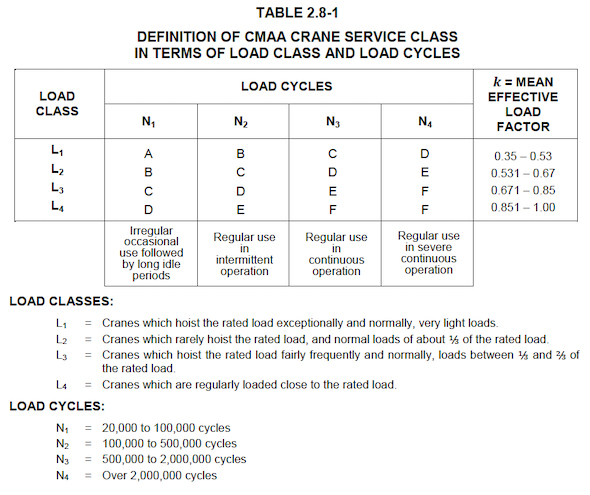

- CMAA 70 – Specifications for Top Running Bridge & Gantry Type Multiple Girder Electric Overhead Traveling Cranes (in Table 2.8-1)

- CMAA 74 – Specifications for Top Running & Under Running Single Girder Electric Traveling Cranes Utilizing Under Running Trolley Hoist (in Table 2.6-1)

The calculation provides a mathematical method of defining the near-infinite variations of possible crane and hoist service conditions and applications. It is based on loading conditions, operating frequency, and length of motion for the various individual movements of the equipment. These methods are then used to design specific crane and hoist components based on load histograms, ultimately providing a safe product for the duration of its expected service life. Please refer to the CMAA specifications for more details on the “k,” or mean effective load factor, calculation of crane duty cycles.

Users attempting to determine the appropriate crane class for their application should discuss their anticipated usage and load type with the crane’s manufacturer, who can help guide them to the best fit solution. CMAA crane classes include:

- Class A – Standby or infrequent usage, such as those found in power utilities or motor rooms, where precise handling of equipment at slow speeds with long idle periods between lifts.

- Class B – Light service, such as those used in repair shops or light warehousing, at slow speeds, with up to five lifts per hour up to maximum rated capacity.

- Class C – Moderate service, such as those installed in machine shops, including handling an average of 50 percent of the rated capacity up to 10 times per hour.

- Class D – Heavy service, such as those deployed in heavy machine shops, foundries, container yards and more, where loads of 50 percent of the rated capacity are handled constantly.

- Class E – Severe service, such as those found in scrap yards, cement mills, lumber mills and more, where the crane makes 20 or more lifts per hour at or near its rated capacity.

- Class F – Continuous severe service, including custom designed specialty cranes, that handle loads approaching the maximum rated capacity non-stop under extreme conditions.

As an example, duty cycle rating means that a CMAA Class A crane designed to handle 10 tons is very different from a CMAA Class F crane also rated for 10 tons. Further of note: The higher the crane’s duty cycle and class of service, the more frequently it will need to be maintained.

CMAA members represent the industry’s leading suppliers of overhead crane systems. They design, manufacture, assemble, install and service overhead cranes and components. CMAA members, with the combined experience of more than 30,000 crane installations in North America in the last decade, are committed to providing products which focus on safety and innovation. The organization offers a variety of resources — including buyers’ guides, OSHA Alliance safety tip and fact sheets, inspection and maintenance checklists, safety seminars and more — via its website at www.MHI.org/CMAA.

Want to learn more about the CMAA crane specifications and technical papers? They are available for purchase, here.