When Should Conductor Bars In Overhead Lifting Systems Be Guarded?

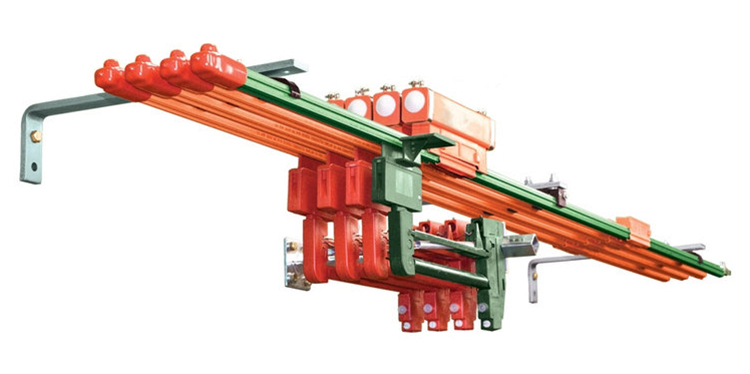

Used to electrify and power overhead crane, monorail, and hoist systems along the runway to power the bridge, or along the bridge to power the trolley, conductor bar systems are typically guarded or isolated with a cover or insulation. This guarding eliminates the risk of an electrical shock should personnel or another component of an overhead lifting system — such as the hoist ropes, block, or load — come into contact with the conductor bars.

Requirements for conductor bar guards are detailed extensively in the Occupational Health and Safety Administration standard OSHA 1910.179. These include:

1910.179(e)(5)(i): If hoisting ropes run near enough to other parts to make fouling or chafing possible, guards shall be installed to prevent this condition.

1910.179(e)(5)(ii): A guard shall be provided to prevent contact between bridge conductors and hoisting ropes if they could come into contact.

1910.179(e)(6)(ii): Guards shall be securely fastened.

1910.179(e)(6)(iii): Each guard shall be capable of supporting without permanent distortion the weight of a 200-pound person unless the guard is located where it is impossible for a person to step on it.

1910.179(g)(2)(i): Electrical equipment shall be so located or enclosed that live parts will not be exposed to accidental contact under normal operating conditions.

1910.179(g)(2)(iii): Guards for live parts shall be substantial and so located that they cannot be accidentally deformed so as to make contact with the live parts.

1910.179(g)(6): Runway conductors. Conductors of the open type mounted on the crane runway beams or overhead shall be so located or so guarded that persons entering or leaving the cab or crane footwalk normally could not come into contact with them.

1910.179(l)(2)(ii): After adjustments and repairs have been made the crane shall not be operated until all guards have been reinstalled, safety devices reactivated and maintenance equipment removed.

Additionally, the American Society of Mechanical Engineers’ standard ASME B30.2: Overhead and Gantry Cranes calls for proper conductor bar guarding in runway conductor systems should the same conditions outlined by OSHA above apply.

The guarding — whether applied to bridge or runway conductor bar systems — should be substantially constructed and fastened securely to ensure its effectiveness. It should be made of material that cannot be easily and accidentally deformed by personnel or contact with a load. Further, it must be installed in a way that ensures nothing can come into contact with the energized conductor bars. If the guards have been removed for maintenance or any other reason, the overhead lifting equipment must not be powered and operated until they have been reinstalled.

Want more details about the safe installation and use of overhead cranes? The Crane Manufacturers Association of America (CMAA), offers CMAA Specification 79: Crane Operator’s Manual, and CMAA Specification 80: Below-the-Hook Lifting Device Operator’s Manual.