Learn All About Workstation Cranes, Monorails And Patented Track Systems In New Infographic From MMA

To help users gain quick insights into workstation cranes, monorails, and patented track systems for overhead material handling and load movement, the Monorail Manufacturers Association (MMA) has developed a new infographic. The reference guide provides an overview of the different styles available across this type of load handling equipment. It also covers the benefits this method of materials movement delivers, as well as introduces the selection of MMA resources and documentation available to help users specify, operate and maintain these systems.

Workstation cranes, monorails, and patented track systems are comprised of an overhead track (or network of tracks) used for lifting and transporting a load along a fixed path. One or more carriers—either powered or manually operated—move along the track. These overhead handling solutions can provide coverage over almost any distance.

They are frequently deployed in applications (particularly manufacturing) where materials are too bulky or heavy to be transported by forklifts or fixed, floor-mounted conveyors. Instead, these systems are used to move and position loads overhead, maximizing the vertical space—as well as the floor space—within a facility.

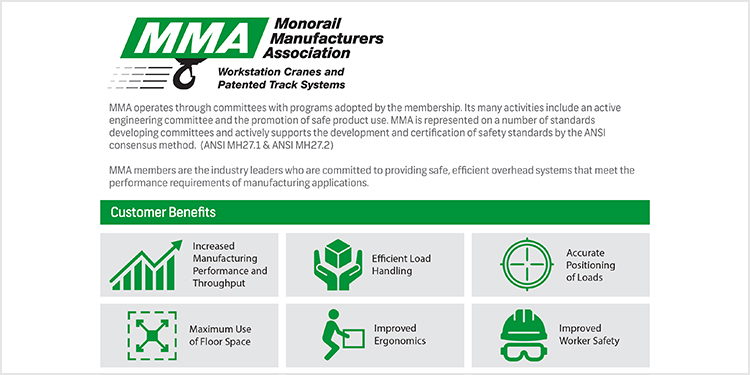

Other benefits of a workstation crane, monorail, or patented track system installation include an increase in performance and throughput; highly efficient movement with precise positioning; improved worker safety and ergonomics; greater durability than other types of load transport equipment; and many more.

The infographic also illustrates two types of track utilized in systems:

- Patented Track – Deployed in under-running crane and monorail installations, these systems feature a continuous run of fixed, overhead track upon which carriers or trolleys travel, and are equipped with trolley hoists to lift, lower and suspend the load.

- Enclosed Track – Used in workstation crane and monorail applications, these systems utilize a fully-contained track section fabricated to form an enclosure that acts as the running surface for the trolley wheels. In addition to allowing for smooth movement, enclosed track systems are ideal for keeping dirt and debris from the running surface.

Initially, the first patented track systems were constructed decommissioned railway rails that were re-rolled and hung for use handling materials in cattle barns. As loads became heavier and service requirements became more precise, tracks were engineered to carry heavier loads over longer spans with a smoother, wear-resistant and hardened rolling surface. Today’s patented track and enclosed track cranes and monorail systems can be manually operated, electrically powered, semi-automatic or fully automatic. Easily customized, they can be installed as part of highly sophisticated, integrated lifting systems, as well as with hoists, vacuum lifters and load manipulators.

A tour of the production floor of many manufacturing facilities shows the extent to which workstation cranes, monorails, or patented track systems are deployed to support various production and assembly processes. Industries served by this type of overhead handling equipment include general manufacturing and assembly, building products, aerospace, metal processing and fabrication, injection molding, pulp and paper, automotive, mining, ship building and many more.

MMA members are the industry’s leading suppliers of overhead monorail systems. They design, manufacture, assemble, install and service enclosed track, patented track under-running cranes and monorail systems, electrified monorail systems and associated components. With the combined experience of thousands of crane installations in North America annually in facilities large to small, are committed to providing proper solutions with a focus on safety and innovation. The organization offers a variety of resources—including a product certification program, guidelines for specifying automated electrified monorail systems, recommended practices for workstation cranes and patented track systems, specifications for both patented track and enclosed track underhung crane and monorail systems, and more—via its website at www.MHI.org/MMA.

Want your own copy of the MMA Infographic? It’s available as a free download, here. Additionally, MMA’s two partners in MHI’s Overhead Alliance—the Hoist Manufacturers Institute (HMI) and the Crane Manufacturers Association of America (CMAA)—have published similar infographics, with HMI’s here and CMAA’s here.