Discover The Latest Overhead Lifting Safety Innovations During Webinar

The third in a set of four sessions shared during the fourth annual Overhead Lifting Safety Webinar Series (www.mhi.org/overheadsafety), “Overhead Lifting Safety Innovations Panel Discussion,” aired on November 11. During the 45-minute presentation, four panelists discussed several new technologies available to help overhead crane and hoist operators, maintenance personnel, owners, safety professionals, purchasers, and specifiers address some of the safety challenges associated with overhead lifting. The panelists included:

- Erin Drake, Associate Director of Product Support and Marketing at R&M Materials Handling Inc.

- Rick Emmer, Business Development Manager in the Automation Division of Columbus McKinnon Corp.

- Jeff Griesemer, Vice President of Engineering and General Manager at American Crane and Equipment Corp.

- Martin Marincic, Director of Product Support and Process at Demag Crane & Components Corp.

First, the panelists emphasized the importance of training as a key means to avoid some of the most common overhead lifting safety challenges. They noted that experienced operators of overhead equipment are more likely to understand how to manipulate a load in such a way as to prevent several safety issues. Among the challenges specifically highlighted were avoiding obstacles in the path of the crane or hoist’s movement; safely operating multiple cranes sharing a common runway; preventing load sway during transport by avoiding erratic movement; and ensuring that a load is properly positioned directly beneath the hoist prior to lifting to circumvent off-center lifts that can cause the load to swing.

Smart crane technologies that intuitively predict a problem in real-time and convey that information to the operator are already available and are expected to become standard in the industry because of their potential to improve efficiency and safety while decreasing downtime. They can help by detecting, communicating, and automatically mitigating excessive load sway, restricted travel areas (also called “no-fly” zones), collisions, off-center lifts, or snags.

Sway control technology uses a mathematical calculation to predict and counteract the natural pendulum effect that occurs when starting or stopping a travel motion. The crane’s drives are programmed to predict and counteract the sway before it starts with no interaction required by the operator. Ideal applications are those that involve lifting sensitive or delicate objects, areas with tight maneuvering space, or extremely high lift heights.

Restricted travel areas prohibit crane hook access within a working envelope to prevent collisions with fixed structures within a facility. The crane can be programmed to avoid specific zones, such as an office area located within a manufacturing floor. Operators can teach a smart crane to avoid a specific area by navigating it around the perimeter of the restricted zone. Devices that enable this function include limit switches for the least complex shaped areas of avoidance to digital laser and encoder devices that enable avoidance of highly complicated boundaries.

Collision avoidance systems utilize onboard safety devices, including laser-based sensors, which can detect and prevent an accident due to an unintended collision. Without such devices, manually or automatically operated cranes and hoists can travel outside of their normal working areas and damage machines, equipment, structures, or people. Ideal applications include runways shared by two or more cranes; two or more hoists attached to a single crane; or end-of-runway slowdown and stopping.

Off-center pick detection technologies are outfitted with sensors that detect the angle of the rope or the misalignment of the load to the hoist drum. When detected, a visual indicator light on the operator’s control can illuminate to alert the user of the unsafe situation. Other technologies can be deployed to either prevent the off-center lift from occurring, or to automatically center the bridge and trolley over the load to ensure proper alignment.

Snag detection systems are based on either friction clutches or hydraulic dampers that quickly and smoothly reduce the energy and inertia of hoist motors. This prevents damage to hoist wire ropes, crane components, and facility structures.

The panelists further discussed integrating different degrees of automation for the operation of cranes, hoists, and monorails to reduce safety risks to users and other facility personnel. It can also improve efficiency and productivity while avoiding the most common operating challenges. Other technologies available for today’s overhead handling systems include condition monitoring systems that share details about the equipment’s functioning for more accurate, timely predictive maintenance. The information can be transmitted to the operator, maintenance staff, owner, or system manufacturer for analysis and evaluation.

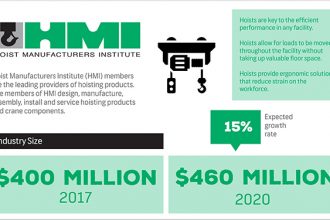

The Overhead Lifting Safety Webinar Series is presented by MHI’s Overhead Alliance, which includes the Crane Manufacturers Association of America (CMAA), the Hoist Manufacturers Institute (HMI), and the Monorail Manufacturers Association (MMA). Designed for owners, operators, maintenance, and safety personnel responsible for overhead lifting cranes and hoists, the series features presentations and Q&A from several industry experts and a representative from the Occupational Safety and Health Administration (OSHA). The other three topics covered include:

- Dangers From Above: Integrating Overhead Lifting into a Resilient Safety Strategy

- OSHA Overhead Lifting Safety Review and Presentation of Upcoming Initiatives

- Best Practices for Safe Operation of Below-the-Hook Lifting Equipment

It’s not too late to gain access to the webinars. All four presentations have been recorded and are available with paid registration of $300, which also includes complimentary copies of safety and specification publications from the Overhead Alliance (a $260 value).

To register to view the Overhead Alliance’s Overhead Lifting Safety Webinar Series, visit www.mhi.org/overheadsafety.