Understand The Basics Of Load Test Requirements

A load test is performed to verify that a specific crane or hoist will safely perform all of its functions while supporting a test load whose weight is at least equal to the equipment’s rated capacity. Because load tests confirm the ability of the crane and hoist to safely operate as intended, they must be completed whenever this overhead lifting equipment is newly installed, altered, repaired, or modified before being placed into service. Existing crane and hoist systems should likewise be load tested at a minimum of once every four years.

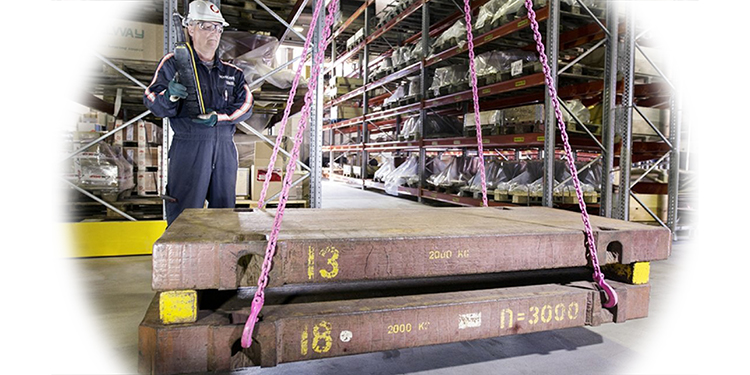

The test load used must be at least 100% and no more than 125% of the equipment’s rated capacity unless otherwise recommended by the original equipment manufacturer (OEM). The weight itself should be certified prior to testing. Load tests should be dynamic, that is they confirm that the overhead crane and hoist function safely and properly as they move to lift and lower the test load, as well as transport it over the length of the bridge and of the runway. All findings and reports should be kept on file for the lifetime of the equipment.

As part of the load test process, both a pre-operational inspection and a periodic inspection should be conducted:

- The pre-operational check assesses the equipment to identify any deficiencies or damage that may impact either the safe operation of the crane and hoist, or affect the load test results. Key areas for evaluation include confirming that the crane or hoist has not been tagged with an out-of-order sign; that all motions align with control device markings; that the hook and latch are not damaged or deformed and work properly; that the wire rope is not broken, kinked, or improperly wound; that the load chain is not worn, stretched, twisted or distorted; that travel limits and hoist limit switches function properly; and that there are no unusual sounds detected.

- The periodic inspection, which should be performed after the load test is complete, is a highly detailed evaluation of the equipment. It includes a comprehensive examination of structural and mechanical components. Reviewed are all girders, end trucks, foot walks, handrails, trolley frames, and cabs. Further, inspection for wear, cracks, or other damage is performed on brakes, shafts, axles, wheels, couplings, sheaves and drums, transmission components, runway structures, and below-the-hook devices. The inspector examines electrical components, indicators, gages, connection points, the trolley and runway rail, bumpers and end stops, covers and guards, and all self-contained electric, hydraulic or gasoline powered generating units.

Because they are so critical to the safe operation of overhead cranes and hoists, there are several standards and specifications that detail load test requirements. These include:

- The Occupational Safety and Health Administration’s standard OSHA 1910.179(b)(3) and OSHA 1910.179(k)(2): Modified or rerated cranes shall be load tested. Test loads shall not be more than 125% of the rated load unless otherwise recommended by the manufacturer. The test reports shall be placed on file where readily available to appointed personnel.

- The American Society of Mechanical Engineers’ standards ASME B30.2: Overhead and Gantry Cranes, ASME B30.16: Overhead Underhung and Stationary Hoists, and ASME B30.17: Cranes and Monorails with Underhung Trolley or Bridge: New, reinstalled, altered, repaired and modified cranes and hoists should be load tested prior to initial use with a test load equal to 100% to 125% of rated load and to include all design functions (lift, lower, traverse length of bridge, traverse length of runway).

- The Crane Manufacturers Association of America standard CMAA Specification 78, section 4.7: Cites the load test requirements of OSHA 1910.179 and states a load test should be performed at a minimum of once every four years at 100% load with a pre-test and post-test inspection per periodic inspection guidelines, and there must be a written report of the load test and inspection results maintained on file for the life of the equipment.

Want to learn more about overhead lifting safety? The three members of the Overhead Alliance — the Crane Manufacturers Association of America (CMAA), Hoist Manufacturers Institute (HMI) and the Monorail Manufacturers Association (MMA) — each offer in-depth resources, standards, specifications, and safety checklists specific to that type of equipment. The three groups recently gained ambassador status with OSHA’s Crane, Hoist and Monorail Alliance (CHM). Together, they will promote cooperative programs with the federal agency, raising awareness of OSHA’s initiatives, outreach, communication, training, and education. They will also continue to provide information, guidance, and access to training resources that help protect the health and safety of personnel operating hoists, cranes. and monorails.