Alert Personnel To Overhead Crane Operation With Audible And Visual Warning Alarms

Warning devices, including both audible alarms that emit an unusual sound and visual alarms that illuminate or flash repeating patterns of light, should be used on both indoor and outdoor overhead cranes whose lifting, lowering, and movement functions are powered. The purpose of these alarms is to alert personnel working, walking, or driving a vehicle within a certain proximity to the overhead lifting equipment — or in its immediate path — that the crane and hoist are about (or have begun) to move. This enhances the overall safety of the operation by enabling workers to get out of the way of the load as it travels throughout a process.

Both the Occupational Safety and Health Administration and the American Society of Mechanical Engineers include audible and visual warning alarm requirements in their standards.

- OSHA 1910.179(i) Warning device: Except for floor-operated cranes, a gong or other effective warning signal shall be provided for each crane equipped with a power traveling mechanism.

- OSHA 1910.179(b)(4) Wind indicators and rail clamps: Outdoor storage bridges shall be provided with automatic rail clamps. A wind-indicating device shall be provided which will give a visible or audible alarm to the bridge operator at a predetermined wind velocity.

- ASME B30.2 Warning devices. A warning device shall be provided for cab and remote operated cranes. Pendant operated cranes should be provided for installations where the ability of the operator to warn persons in the path of the load is impaired. The operator shall activate the warning device before starting the bridge or trolley motion of a crane.

There are a variety of recommended best practices for the selection, application, and use of audible and visual warning alarms. When choosing between the two types, it is important to consider the working conditions in which the overhead lifting equipment operates and select the device that best accommodates the surroundings. For example, in a particularly noisy operation an audible alarm might not be heard by personnel; in that case a visual device would be a better choice. Conversely, in a bright facility or one where air contamination is prevalent a flashing light may not be visually discernable to workers, making an audible alarm more appropriate for the application.

When specifying an audible warning device, it should project sound at a minimum of 100 decibels. However, a given facility may have other requirements for how far away from the equipment the noise should be heard. Another consideration is the ambient noise level during normal operation and how easily the audible warning can be perceived within a pre-defined range from its source.

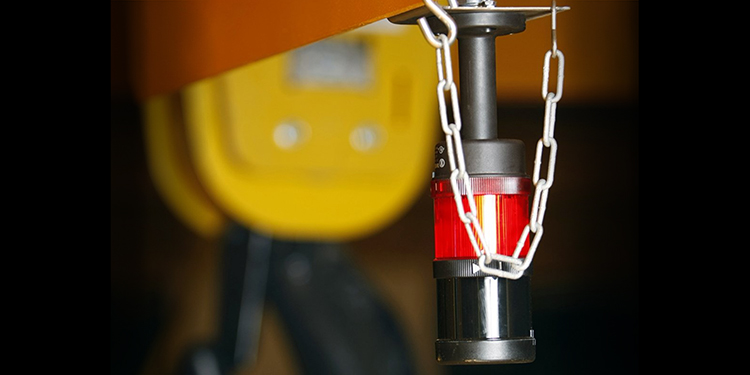

Facilities that choose visual warning lights for their overhead cranes should select the color(s) that can be most easily seen, clearly indicate a warning about a safety condition, and do not match any other warning lights already in use. Further, the visual alert devices should be located so that their light is easily seen by both the crane operator and any others working in the area.

Regardless of which type of alarm device is chosen, it should be mounted such that people stationed in the locations that interface with the cranes are alerted to their movement. Further, the owner of any overhead lifting equipment should check both state and local regulations for any specific requirements or codes regarding the use of audible and visual warning devices for overhead cranes.

Audible and visual warning alarms are not the only safety devices available for overhead lifting equipment. To learn more about the latest safety innovations for crane, hoist, and monorail systems, view this webinar, presented by the three members of the Overhead Alliance — the Crane Manufacturers Association of America (CMAA), Hoist Manufacturers Institute (HMI) and the Monorail Manufacturers Association (MMA) — as part of the fourth annual Overhead Lifting Safety Webinar Series.