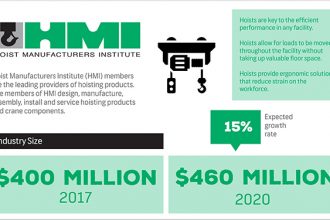

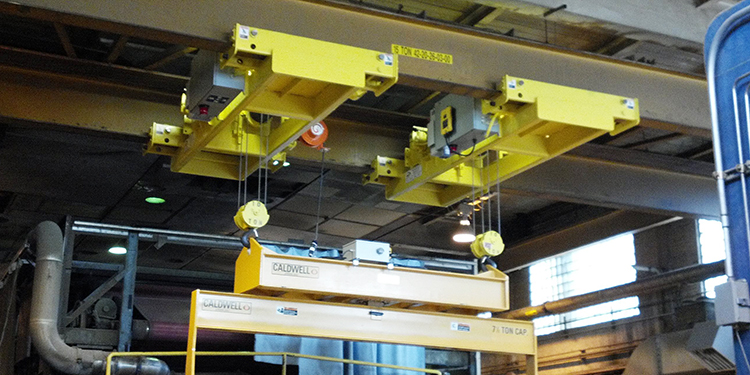

To ensure the safety and efficiency of an overhead lifting operation, it is crucial that the design of the hoist used to connect a load to an overhead crane, monorail, or workstation crane matches the specific needs of the application. That’s why it’s important to determine the proper Hoist Duty Service Classification — which is based on the hoist’s ability to operate under varying loading conditions and operating cycles — prior to purchasing the device. The topic is explored in detail in a recent article in MHI Solutions magazine, with input contributed from the members of the Hoist Manufacturers Institute (HMI).

As the article explains, a number of organizations publish Hoist Duty Service Classifications. These include the American Society of Mechanical Engineers (ASME), the Crane Manufacturers Association of America (CMAA), the European Federation of Materials Handling (FEM), and the International Organization for Standardization (ISO). However, each of these standards uses different nomenclature for their classifications, with little correspondence between the definitions from one organization to the other.

To help hoist users as they compare these different classifications, HMI has published a document that details the different types, terminology and standards applicable in the U.S. and elsewhere in the world. The “Compendium of Basic Information and Standards for Hoists” is offered as a free downloadable reference for users as they navigate both mandatory regulations and voluntary recommendations for usage.

When determining which hoist has a duty cycle that is right for a given application, a company must first define certain operating parameters. These include:

- The anticipated number of lifts per hour.

- The total number of lifts per shift.

- The number of shifts per day.

- The maximum number of starts and stops per hour

- The average distance the load is to be raised or lowered.

- The average weight to be lifted.

- The maximum weight to be lifted.

- The frequency of lifts with maximum weight.

Having this information will help an industrial hoist and/or crane company recommend the optimally sized hoist for the company’s application to ensure a safe and efficient operation. Applications equipped with an undersized hoist will experience a shorter lifespan; conversely, an oversized hoist will require more expensive maintenance and replacement parts.

To read the full article, click here.

Looking for more information on hoist systems? The members of the Hoist Manufacturers Institute (HMI) offer a variety of resources — including a comprehensive library of product guides; a hoist certification program; OSHA Alliance safety tip sheets, fact sheets and quick cards; multiple technical papers and more — via its website at www.MHI.org/hmi.