Workstation Cranes 101: An Overview Of This Ergonomic Solution

Frequently found in manufacturing and assembly operations where workers need to lift, handle, and move heavy objects to perform various processes upon them, workstation cranes generally handle loads from 150 to 4,000 pounds. Dedicated to a specific location or area, these cranes are outfitted with a vertical lifting device — such as a hoist or other attachment — that suspends the load while the operator guides and positions it manually, or a powered trolley moves it mechanically. These functions improve worker safety and ergonomics by eliminating the physical exertion, fatigue, and risk of injuries associated with lifting and pushing or pulling loads.

There are three primary types of workstation cranes. They include…

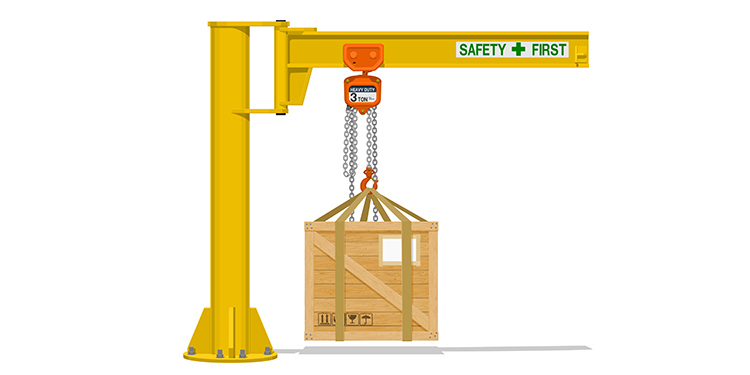

Jib Cranes: Mounted to the wall or the floor, this stationary crane features a cantilevered bridge (girder) supported by a stationary, vertical support on one end, allowing it to move its payload in a 180-degree arc or 360-degree circle. Its hoist is mounted on the horizontal boom. Depending on the application, jib cranes can be mounted in a variety of ways, including to a column (either a self-supporting mast or a structural column within the building); to a facility wall; or on a runway (for lateral movement) attached to a wall.

Bridge Crane: Similar to their large-load overhead crane cousins, these lighter-duty cranes are also capable of covering a rectangular area. They are mounted overhead to a building’s columns, trusses or frames — or via a free-standing structure of columns. Used for loading and unloading, bridge cranes incorporate a hoist and trolleys connected to a bridge beam for side-to-side and vertical movement.

Gantry Crane: Sometimes called a free-standing or floor-supported crane, the bridge beam is supported by two (or more) legs that travel atop fixed rails in the facility floor or on wheels. Depending on the configuration of the facility and available floorspace, there are different types of gantry cranes, including cantilevered, semi-gantry (one leg fixed, the other travels in arc or circle around the center point; also called a single-leg crane), or double-leg gantry.

Want to learn more about workstation cranes and how they can help your operators be both safer and more productive? The members of the Monorail Manufacturers Association (MMA) are the industry’s leading suppliers of workstation crane systems. The group offers a variety of resources—including a product certification program, recommended practices for workstation cranes and patented track systems, and more—via its website at www.MHI.org/MMA.