How Digital Trends Will Push Overhead Lifting To Greater Heights

The original version of this article by MHI CEO John Paxton previously appeared on HoistMagazine.com With the advent of digital intelligence, overhead lifting components are smarter — and safer — than ever before. The digital trends impacting the design of ...

Monorail Manufacturers Association Celebrates 90 Years Of Safe Monorail Best ...

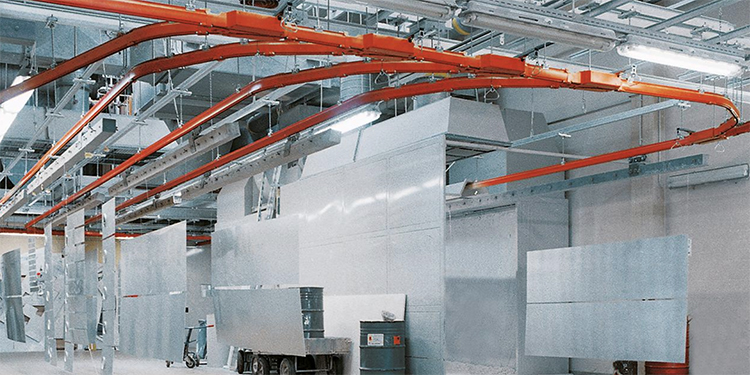

The Monorail Manufacturers Association (MMA), founded in 1933, is celebrating its 90th anniversary. An independent, incorporated trade association affiliated with MHI, MMA members are leading suppliers of patented and enclosed track underhung workstation cranes and monorail systems. MMA is also ...

The Two Underhung Crane And Monorail Specifications And Standards You ...

The members of the Monorail Manufacturers Association (MMA) develop and publish technical standards and specifications for the safe design, engineering, manufacturing, operation, and service of of underhung cranes and monorails. The standards, produced by the MMA Engineering Committee, cover both ...

Four Ergonomic Lifting Solutions That Cut Repetitive Stress Injury Risks

Workplace injuries can result from a single overexertion incident in which a worker attempts to move, position, or lift a very large, heavy load. However, they can also occur when an employee performs the same task repeatedly. Whether in manufacturing, ...

Overhead Safety Promoted By The Overhead Alliance

To help owners design, install, and operate the most reliable, dependable, and safest equipment possible, the industry groups of the Overhead Alliance of MHI routinely release new and updated standards and specifications. The publications cover overhead cranes, monorails, hoists, and ...

How Overhead Lifting Equipment Enhances Workplace Safety

This article previously appeared in the February 2023 issue of Workplace Material Handling & Safety magazine. Contributed by the members of the Overhead Alliance, which is comprised of the Crane Manufacturers Association of America (CMAA), the Hoist Manufacturers Institute (HMI), ...

Monorail And Underhung Crane Standards Help Eliminate Workplace Safety Risks

When moving loads overhead on a patented track or enclosed track monorail or with underhung workstation cranes, the safety of the operator and of any personnel working underneath the equipment is critical. To help facilities ensure their equipment is inherently ...

5 Signs That A Workstation Crane Needs To Be Replaced

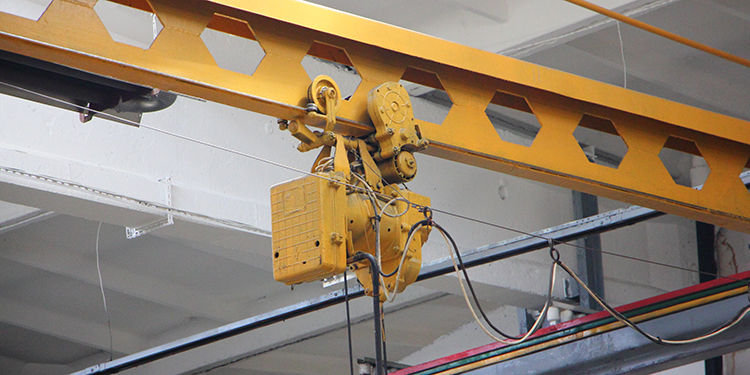

Typically designed to loads ranging from 150 to 4,000 pounds, workstation cranes are dedicated to a specific area or location and are equipped with a load handling device, such as a hoist, that suspends the load. Offered in jib, bridge, ...

MMA-Certified: The Advantages For Owners And Operators Of Monorails And ...

To assure buyers of patented track and enclosed track monorails and workstation cranes that the products are constructed in conformance with standards established by the Monorail Manufacturers Association (MMA), the group offers manufacturers the ability to have their products MMA-Certified. ...

The “Dos And Don’ts” Of Workstation Cranes

Workstation cranes — offered in jib, bridge, and gantry styles — are often deployed in manufacturing and assembly operations where operators must lift, handle, and move heavy objects as part of a work process. Generally handling loads ranging from 150 ...