The members of the Monorail Manufacturers Association (MMA) develop and publish technical standards and specifications for the safe design, engineering, manufacturing, operation, and service of of underhung cranes and monorails. The standards, produced by the MMA Engineering Committee, cover both patented track and enclosed track systems. MMA standards are the leading global resource for the safe construction and utilization of overhead lifting systems. They are part of MMA’s library of technical publications, which also includes specification guidelines and recommended practices for safety, maintenance, and use. To ensure the safest equipment and operation, here are the two underhung crane and monorail standards you should know.

The members of the Monorail Manufacturers Association (MMA) develop and publish technical standards and specifications for the safe design, engineering, manufacturing, operation, and service of of underhung cranes and monorails. The standards, produced by the MMA Engineering Committee, cover both patented track and enclosed track systems. MMA standards are the leading global resource for the safe construction and utilization of overhead lifting systems. They are part of MMA’s library of technical publications, which also includes specification guidelines and recommended practices for safety, maintenance, and use. To ensure the safest equipment and operation, here are the two underhung crane and monorail standards you should know.

MMA Technical Standards

MMA Standard ANSI MH27.1: Patented Track Underhung Cranes and Monorail Systems

MMA Standard ANSI MH27.1: Patented Track Underhung Cranes and Monorail Systems

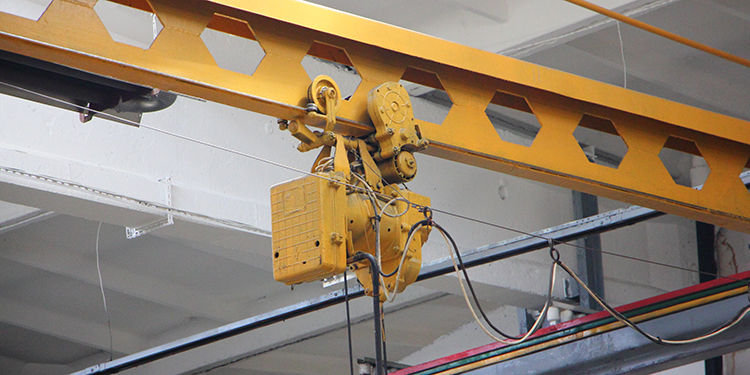

MMA’s ANSI MH27.1 provides guidance on patented track underhung crane and monorail systems and components. It applies to underhung cranes whose end trucks operate on the lower flange of an inverted-T profile. Additionally, it covers curves, switches, transfer devices, trolleys, lift and drop sections, and associated equipment.

The standard includes a comprehensive section of terms and definitions. It details duty service classifications and the factors that impact those assignments, such as service conditions, load distribution, work distribution, number of stops and starts, hazardous locations, and more. Design criteria for all components, tracks, and load factors is also included.

MMA Standard ANSI MH27.2: Enclosed Track Underhung Cranes and Monorail Systems

MMA Standard ANSI MH27.2: Enclosed Track Underhung Cranes and Monorail Systems

MMA’s ANSI MH27.2 offers guidance regarding design practices and performance testing criteria for enclosed track underhung cranes and monorails. In these systems, the carriers’ end trucks operate on the internal flange of a runway using an enclosed track section. It also applies to trolleys operating on single-track monorail systems. Curves, switches, transfer devices, lift and drop sections, and associated equipment are also covered.

An extensive listing in the standard details key terms and definitions for all components discussed. A section dedicated to duty service classifications explores the factors that impact those assignments. These include service conditions, load distribution, work distribution, number of stops and starts, hazardous locations, and more. The standard also outlines design criteria for all components, tracks, and load factors.

Both Standards Currently in Revision Process

Both underhung crane and monorail standards are currently under review. As part of the revision process, users of the standards can provide input to the content and the updates. Persons interested in contributing to the review process should contact Patrick Davison, MHI’s Director of Standards, at pdavison@mhi.org.

Get More Underhung Crane and Monorail Information

Want to learn more ways underhung cranes and monorails can help workers be safer and more productive? The members of the Monorail Manufacturers Association (MMA) are the industry’s leading suppliers of workstation crane systems. The group offers a variety of resources—including a product certification program, recommended practices for workstation cranes and patented track systems, and more—via its website at www.MHI.org/MMA.