Monorail Manufacturers Association Celebrates 90 Years Of Safe Monorail Best Practices

The Monorail Manufacturers Association (MMA), founded in 1933, is celebrating its 90th anniversary. An independent, incorporated trade association affiliated with MHI, MMA members are leading suppliers of patented and enclosed track underhung workstation cranes and monorail systems. MMA is also the industry’s leading source of safe monorail best practices.

“MMA initially formed in Pittsburgh, Pennsylvania by a group of manufacturers who sought to ensure the safe application and use of these overhead lifting solutions,” said Rose Haire, MMA Managing Executive. “While the organization’s headquarters have moved over the years, its commitment to safety and best practices in the construction and use of this vital equipment has not.”

Haire also noted that MMA is in good company celebrating 90 years. Several iconic brands and inventions — such as SPAM, Monopoly, FM radio, and drive-in movies — also appeared for the first time in 1933.

MMA Standards Ensure Safety

MMA operates through committees with programs and policies reviewed and adopted by the membership with representation from each member company. Its engineering committee writes and regularly updates standards approved and published by the American National Standards Institute (ANSI).

Written to help facility owners ensure the safety of their equipment, operators, and personnel, the standards cover the components and operation of both patented and enclosed track underhung monorails and workstation crane systems. They include:

- ANSI MH27.1 – Patented Track Underhung Cranes & Monorail Systems

- ANSI MH27.2 – Enclosed Track Underhung Cranes & Monorail Systems

The standards contain information about specifying and selecting the optimal monorail or underhung crane system for a given application. They also detail correct installation practices, and best practice recommendations for the proper use, maintenance, and inspection of the equipment. Since most safety issues surrounding these kinds of overhead equipment are rooted in human error, the standards also help owners and operators gain a more better understanding of the technologies’ intended function and their correct operation.

“Both standards are currently under review as part of the ongoing revisions and updates process,” continued Haire. “The MMA engineering committee is soliciting input about content and updates from users of the standards. Anyone interested in contributing to the review process should contact my colleague Patrick Davison, MHI’s Director of Standards at pdavison@mhi.org.”

Other MMA Resources

In addition to the ANSI standards, MMA offers a variety of resources to further promote best safety practices for underhung workstation cranes and monorails. These include a product certification program that ensure buyers that MMA-Certified equipment meets ANSI MH27.1 or ANSI MH27.2. An independent professional engineer registered in the U.S. verifies, signs, and seals a technical declaration of conformity attesting to that fact.

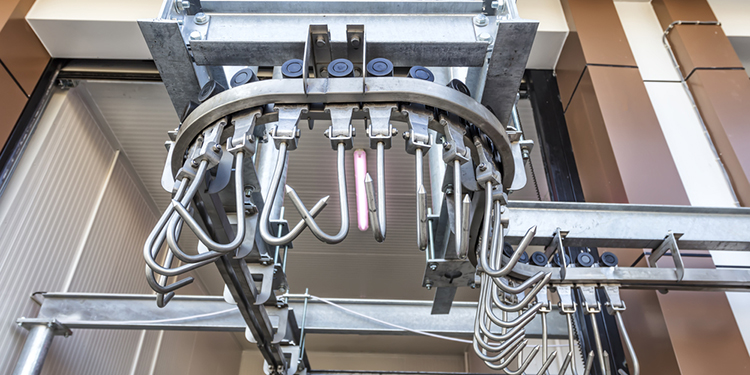

MMA also publishes a comprehensive set of “Guidelines for Specifying Automated Electrified Monorail Systems.” This document reviews general specifications, as well as key details surrounding the type of track, conductor bars, vehicles and carriers used, turns, inclines, maintenance spurs, and more.

Further, the association has checklists of best practices for the safe design, operation, use, and service of both monorails and workstation cranes. These easy to understand “dos and don’ts” recommendations enhance both the integrity and reliability of the equipment. They also reduce the risk of injury to employees operating the system or working near it.

Several Leading Manufacturers Among MMA Membership

The members of MMA participate voluntarily in the organization. They represent the leading manufacturers of overhead workstation cranes and monorail systems. Current MMA members include:

- ACCO Material Handling Solutions

- Columbus McKinnon (CMCO)

- Demag Cranes and Components

- Gorbel

- Harrington Hoists

- Ingersoll Rand Company

- Schmalz

- Spanco

- TC/American Crane Company

Learn More About MMA

To connect with MMA’s members or to learn more about safe monorail best practices and safety recommendations for overhead workstation cranes, visit the association’s website at www.MHI.org/MMA.