Monorail Splice Connections: Best Practices For Design And Use

Monorails transport heavy, bulky materials throughout an operation, maximizing a building’s vertical space by moving loads overhead. They consist of a continuous run of fixed, overhead track and carriers, end trucks or trolleys suspended from the track that move the load horizontally, vertically and laterally. The track itself — or network of tracks — can be constructed from multiple pieces to span nearly any distance with the use of monorail splice connections (sometimes called track joints or couplings).

Whether the system is built with patented track or enclosed track runways, some monorail system will require splice connections. That’s because the majority of manufacturers provide rails in standard, fixed lengths that can be easily transported to an installation site via tractor trailer. Therefore, to achieve a desired coverage area or layout in a new installation, to modify an existing system to accommodate a new process or expanded facility, or to relocate and reuse existing equipment in a different location, splice connections must be used.

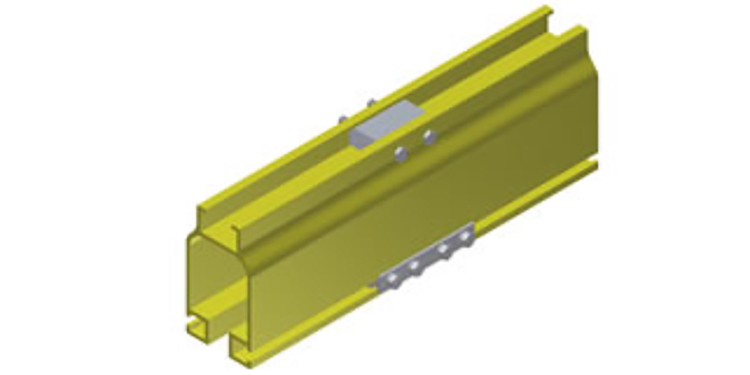

Splices can consist of a small connector piece bolted, welded, or both bolted and welded, to the two sections, securing the two ends together tightly. For structural integrity of the monorail system, putting a splice connection on a load-bearing overhanging portion of a rail is not recommended. Rather, splices should only be placed in situations where the rail is supported at the splice. This ensures that the track in the area of the splice has the same load bearing capacity of areas of continuous rail and preventing a structural failure of the system. Additionally, splice connections are typically used on runway and monorail track sections; however, some manufactures allow splicing of bridge sections under certain conditions.

Standards published by the Monorail Manufacturers Association (MMA) of MHI for both types of monorails include sections on splice connections.

- ANSI MH27.1 Patented Track Underhung Cranes and Monorail Systems, section 6(f) calls for: “Web type or other suitable couplings (splices) shall be provided at all track joints. The maximum gap between ends of the load carrying flange shall not exceed 1/16 in. (1.5 mm). Track running surface misalignment at joints, following installation and adjustment, shall not exceed 1/32 in. (1 mm).”

- ANSI MH27.2 Enclosed Track Underhung Cranes and Monorail Systems, section 6(d) states: “Suitable splices shall be provided at all track joints. The maximum gap between ends of the load carrying flange shall not exceed 1/16 in. (1.5 mm). Track shall be supported at all splice locations.” Further, section 6(h) notes: “Track running-surface misalignment at joints, following installation and adjustment, shall not exceed 1/32 in. (1 mm).”

In both track types, a gap larger than 1/16-inch can create a bump or other small impact as the wheels of the trolley pass over the splice connection. Improper alignment or larger gaps in the connection can cause premature wheel wear and even failure. It can also slow down the travel of the trolley. Conversely, proper alignment of running surface will ensure that the wheels transition smoothly between sections, extending the life of the equipment and keeping the load handling process flowing steadily.

Other best practices for monorail track splice design and use include:

- Always follow manufacturer’s recommendations for spliced connections. This is critical for safe operation of monorail systems.

- When adding a splice connection into an existing system, consult with the original equipment manufacturer to ensure the work is performed safely and properly.

- Placement of splice connections should follow the monorail manufacturer’s specifications.

- Inspect all splices at regular intervals to verify that all hardware is securely fastened and that any gaps that exist between the two pieces of track are within the limits recommended by the ANSI standards.

Looking for more information about how a monorail system might benefit your operation? The members of the Monorail Manufacturers Association (MMA) are the industry’s leading suppliers of overhead monorail systems. The group offers a variety of resources—including a product certification program, guidelines for specifying automated electrified monorail systems, recommended practices for workstation cranes and patented track systems, specifications for both patented track and enclosed track underhung crane and monorail systems, and more—via its website at www.MHI.org/MMA.