Overhead Alliance Leaders Discuss Equipment Benefits, Factors To Consider In Podcast

In a recent episode of MHIcast — MHI’s podcast featuring the latest insights and trends in the material handling, logistics, and supply chain industries — the leadership of the Overhead Alliance discussed the benefits of overhead handling, as well as key factors to consider when selecting this type of equipment. Sharing their thoughts were Josh Arwood, president of the Crane Manufacturers Association of America (CMAA); Mark Arthur, president of the Hoist Manufacturers Institute (HMI); and Jerry Eischens, president of the Monorail Manufacturers Association (MMA). Together, these three organizations form the Overhead Alliance.

Collectively, the Overhead Alliance offers a variety of brand-neutral, unbiased, industry-focused resources that raise awareness of overhead handling as an alternative solution to ground-based transport methodologies, such as fixed conveyor and forklifts. Its members have also compiled a library of case studies, free informational downloads, technical papers, online learning resources and buyers’ guides. These publications help organizations considering an overhead handling solution gain greater insight into the broad range of equipment available for lifting, transporting and positioning loads in manufacturing and distribution facilities.

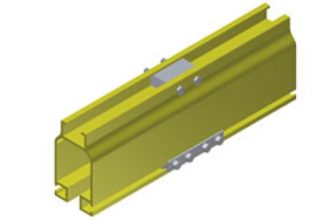

During the 10-minute podcast, Arwood, Arthur and Eischens explained that cranes, monorails and hoists come in a wide variety of sizes and load capacities and a nearly endless assortment of customizable configurations. Because they move loads overhead, they can reach areas within a facility that ground-based transport solutions cannot. Further, they free up floor space to maximize a building’s layout. And, because they are nearly always powered by electricity, overhead handling equipment does not produce emissions or exhaust that could be harmful to workers as well as negatively impact an organization’s sustainability initiatives.

The broad diversity of possible options in cranes, monorails and hoists can make choosing the right solution for a specific application challenging. When assessing the possibilities, the trio recommended starting with the type and weight of the load to be handled, then determining the transport need the equipment will fill. Will it be moving loads from one end of an operation to another (an ideal for solution for cranes or monorails)? Or, will it be dedicated to a single workstation for use by an operator in an assembly operation (an optimal situation for a workstation or jib crane)?

Additionally, the Overhead Alliance leaders encouraged organizations entering the design phase of a greenfield construction project to seek guidance from overhead handling experts sooner than later. That ensures the structural capacity of the building itself will support integrated overhead handling equipment and save both cost and time. Otherwise, an additional structural system will likely need to be constructed within the facility to support the overhead equipment and the loads it handles, which can add both time and expense to the project. Likewise, those considering the installation of an overhead handling system in an existing building should also consult with an expert to verify both structural integrity and adequate clearances prior to purchasing the equipment.

Looking for more ways overhead handling systems can improve your operation’s safety and productivity? Download the free Overhead Alliance publication, “Expand Your Possibilities. Discover the Potential. Choose Overhead Lifting.”