Understanding Operational And Over Travel Upper Limit Switch Requirements For Wire Rope Hoists

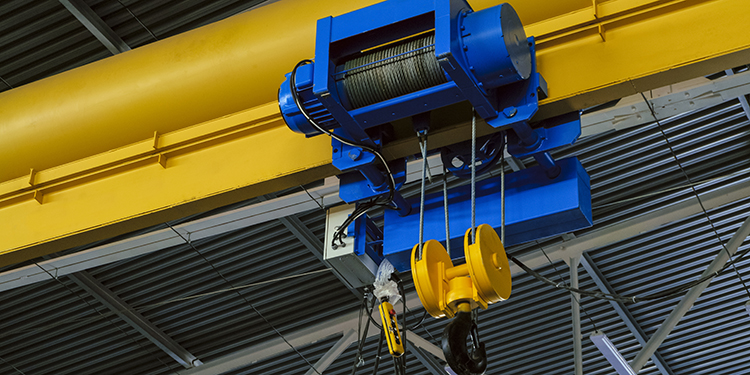

As an important element of overhead handling safety, upper limit switches are electro-mechanical devices used throughout crane, hoist, and monorail installations. When applied to wire rope hoists, upper limit switches restrict their lifting motion at a certain point to prevent an accident. Because hoists are used primarily for vertical raising and lowering of freely suspended, unguided heavy equipment or material loads, lifting the hoist too high could cause the load hook block to come into contact with the hoist or other part of the crane or overhead lifting structure. This is often referred to as “two-blocking the hoist” and can result in damage to the equipment and in the load potentially being dropped. For that reason, there are typically two types of upper limit switches applied to wire rope hoists:

- An operational limit switch triggered by a certain number of wire rope drum rotations that engages to slow the hoist’s upward travel as it approaches the crane; and

- A final/over travel limit switch, activated by the actual hook block, that stops the hoist’s travel prior to it contacting the hoisting structure. The most common type of final/over travel limit switches are block operated. They typically have a paddle, weight, or other device that activates the switch when contacted or obstructed by the block.

Defining Limit Switches

The Occupational Safety and Health Administration’s OSHA 1910.179(a)(60) defines a limit switch as “a switch which is operated by some part or motion of a power-driven machine or equipment to alter the electric circuit associated with the machine or equipment.” Its application “limits equipment motion or takes control of particular functions without action of the operator when a limiting condition is reached,” according to the American Society of Mechanical Engineers’ ASME B30.16 specification.

Additionally, the Crane Manufacturers Association of America’s two specifications, CMAA 70 and CMAA 74, define a limit switch as “a device designed to cut off the power automatically at or near the limit of travel for a crane motion (lift-lower, trolley traverse or bridge traverse).”

Upper Limit Switch Requirements for Wire Rope Hoists

OSHA, ASME, and CMAA have all established several requirements for the installation and safe use of limit switches on wire rope hoists.

- OSHA Section 1910.179(g)(5)(iv) states that the hoisting motion of all electric traveling cranes must be supplied with an over travel limit switch in the hoisting (up) direction.

- OSHA Section 1910.179(n)(4)(ii) prohibits using the hoist limit switch which controls the upper limit of travel of the load block as an operating control.

- ASME B30.2 and B30.16 both call for powered hoists to be designed and constructed in a way that prevents an empty or loaded load hook from exceeding the upper limit of travel. Wire rope hoists that incorporate a geared or other limit switch or device that operates in relation to drum turns must also be equipped with an additional upper limit switch or device that operates independent of drum turns.

- CMAA 70 and 74 both state that the hoist motion of all cranes shall be equipped with an over travel limit switch in the raising direction to stop hoisting motion. Further, if the limit switch operates off the rotation of the drum, a secondary limit switch that operates independently of drum turns shall be provided.

All three organizations’ specifications require that the trip setting of hoist limit switches first be confirmed via a series of tests conducted with an empty hook traveling at increasing speeds up to the maximum speed prior to commissioning. The testing verifies that the actuating mechanism of the limit switch is located so that it activates the switch under all conditions and in sufficient time to prevent contact of the hook or hook block with any part of the trolley.

OSHA, ASME, and CMAA also forbid the use of a hoist’s upper limit switch as an operating control, as this could increase the risk of equipment damage or a load drop. Prior to the start of each shift, operators are required to test the upper limit switch devices on powered hoists to verify they are functional. The devices should be assessed during frequent and period inspections as well.

Best Practices

In addition to these requirements, several best practices are recommended for crane or hoist operators and owners to ensure the functionality and safe use of hoists’ upper limit switches. These include:

- Always test the operation of the primary upper limit switch for the hoisting motion before each shift.

- Always immediately report any faulty limit switches to supervisors, managers, or equipment owners.

- Never use a hoist with a faulty limit switch.

- Always pay attention to the location of the load block in relation to the hoist as the lift is in progress.

- Always be aware of the size and shape of the actual load. When lifting an irregularly shaped object, it may be possible for some part of the load to strike the hoist or other structure before the load block connects with the limit switch.

- Never use the hoist upper limit switch to stop the hoist under normal operation.

Want to learn more about overhead lifting safety? The three members of the Overhead Alliance — the Crane Manufacturers Association of America (CMAA), Hoist Manufacturers Institute (HMI) and the Monorail Manufacturers Association (MMA) — each offer in-depth resources, standards, specifications, and safety checklists specific to that type of equipment.