Four Ways Overhead Lifting Solutions’ Return On Investment Can Be Significant

This is the eighth in a series of posts detailing 13 reasons why overhead lifting and handling technologies — specifically cranes, hoists, and monorails — can improve a manufacturing or distribution operation’s efficiency, productivity, safety, and sustainability. Read more in the free Overhead Alliance publication, “Expand Your Possibilities. Discover the Potential. Choose Overhead Lifting.”

There are a variety of options available for the transport, lifting, positioning, and placement of loads in warehouses and manufacturing facilities. These include overhead lifting solutions—such as cranes, hoists, and monorails—lift trucks, fixed conveyors, autonomous mobile robots (AMRs), and automatic guided vehicles (AGVs). When comparing the choices, however, it’s important to focus on more than just the initial investment cost. Before making a selection, it’s also wise to consider the overall life cycle and ongoing operational costs associated with such equipment before making a selection. Often, this comparison results in the discovery that overhead lifting solutions’ return on investment (ROI) is more significant than other options.

Four Factors in Calculating Overhead Lifting Solutions’ Return on Investment

1. Long-lasting durability.

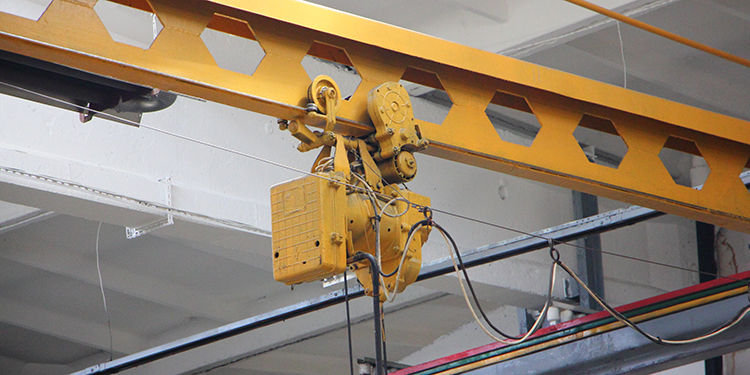

Overhead handling cranes, hoists, and monorails feature extremely durable construction. Designed, engineered, and built with heavy-duty, long-lasting materials, overhead lifting equipment provides reliable service, often for decades. Compared to floor-based transport equipment, overhead systems also feature far fewer wear and service points. This enables them to perform reliably and for a longer lifespan than other options.

2. Less frequent maintenance.

Cranes, hoists, and monorails require less frequent maintenance than other types of load transport and placement equipment. They also incorporate fewer moving parts. This makes their service and upkeep quicker and easier to complete. Lower maintenance and repair requirements subsequently minimize both planned and unplanned downtime. Further, labor, service parts, and other costs for overhead lifting systems are lower when compared to floor-based transport options.

3. Lower depreciation.

Unlike floor-based load handling equipment, overhead lifting solutions’ return on investment comes from how it retains its value. Depreciation is not nearly as significant an issue for cranes, hoists, and monorails because their installation is an upgrade to the handling and storage capacity [LINK] of an operation. With the majority of these systems permanently integrated into a building structure, they often contribute to an increase in the facility’s overall real estate value.

4. Better configuration flexibility.

Nearly every overhead lifting solution incorporates some degree of customization to match specific application needs. Likewise, the configuration of each crane, hoist, or monorail system matches an installation’s unique environment to achieve maximum operational productivity and efficiency. Yet most combine a standard hoist, crane, and monorail component designs for affordability. This construction methodology also results in tremendous flexibility both prior to and after system implementation, as the components can accommodate a wide range of possible configurations (and price points). It also means that an installed system can be re-configured, converted, or modified to align with to an operation’s changing overhead lifting needs.

What other cost, efficiency, and productivity benefits contribute to overhead lifting solutions’ return on investment?

Discover 13 different ways crane, hoist, and monorail systems enhance manufacturing and distribution operations in the free publication, “Expand Your Possibilities. Discover the Potential. Choose Overhead Lifting.” The document is produced by MHI’s Overhead Alliance (which includes the Crane Manufacturers Association of America (CMAA), the Hoist Manufacturers Institute (HMI), and the Monorail Manufacturers Association (MMA)).