Adding Switches, Curves To Monorails Increases Material Movement Flexibility

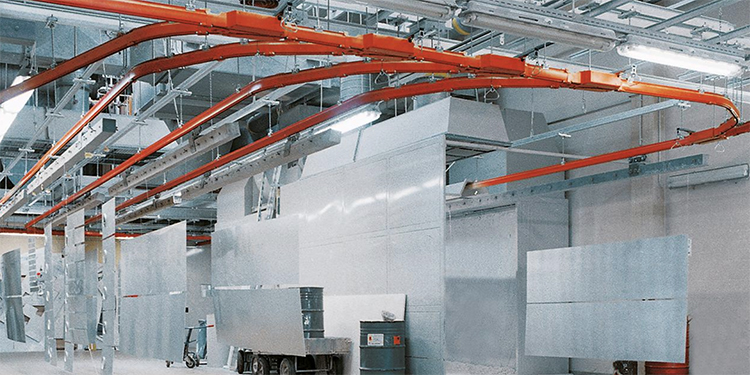

While many companies use monorails to move workpieces, products, or other loads from point A to point B, applications that require more flexibility can have curves and switches integrated into the system. Curves allow for direction changes to avoid obstacles or route a load to a choice of locations. Track switches enable a load carrier or trolley to transition from one track to another seamlessly, diverging or curving off along a branch path and connecting to multiple work cells. Frequently found in foundries, industrial laundries, veterinary schools, and jet engine test facilities, monorails applications with curves and switches — and key considerations for their design and layout — are explored in a recent article in MHI Solutions magazine, with input contributed from the members of the Monorail Manufacturers Association (MMA).

Whether an installation uses a patented track or an enclosed track monorail system, if the supplier is a member of MMA, the owner can be assured that the equipment has been designed to meet or exceed ANSI standards (MH27.1 for patented track; MH27.2 for enclosed track). Among the components covered in the standards are curves, switches, transfer devices, trolleys, lift and drop sections, and associated equipment.

Because each provides consistent flange widths and profiles, existing installations of both enclosed track and patented track monorails can be easily modified with the addition of curves and switches. This inherent design flexibility accommodates changes in processes, operations, or unforeseen future modifications to a facility. However, when adding curves and switches to a monorail, it is important to investigate the ability of the overhead facility structure to bear the weight of the system prior to its design and implementation; if not, a freestanding structure can be constructed to support the system.

Functioning mechanically, switches can be operated manually or electrically powered. Manual switches utilize pull chains; powered switches are driven by either electric motors or air cylinders. Integrated safety devices, such as electric baffles, ensure motor-driven carriers don’t enter a switch that is not set to receive it. Other switching component options include:

- Turntables, which incorporate four branch connections. Acting like a four-way intersection, a turntable allows a load and its carrier to be rotated 90 degrees to the left or right, then branch off immediately.

- Crane-Monorail Interlocks, which enable the safe transfer of a load between a crane system and a monorail. The crane picks and places items from different locations within its rectangular coverage area.

To read the full article, click here.

Want to learn more about the other the advantages offered by overhead handling systems? MHI’s Overhead Alliance — comprised of the Crane Manufacturers Association of America (CMAA), the Hoist Manufacturers Institute (HMI), and the Monorail Manufacturers Association (MMA) — details 13 different ways these lifting solutions benefit facilities in the free publication, “Expand Your Possibilities. Discover the Potential. Choose Overhead Lifting.”