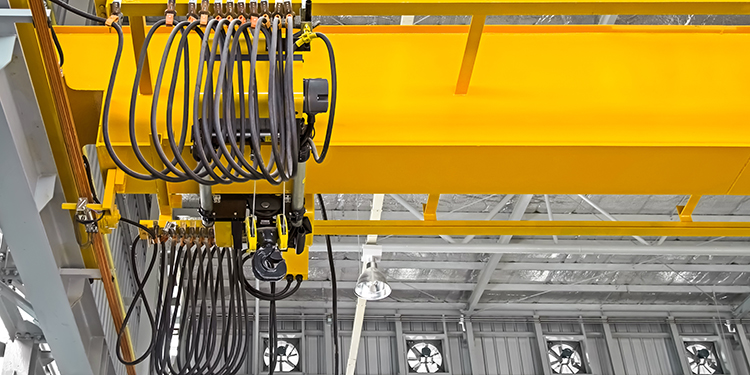

How Pre-Shift Hoist Inspections Keep An Overhead Lifting Operation Safe

Before using a wire rope, chain, or lever hoist for the first time during a shift or day, it’s important that the operator perform a pre-shift hoist inspection. These inspections, recommended by the Hoist Manufacturers Institute (HMI), ensure the safety of personnel and the proper functioning of the hoist. The HMI Technical Committee recently presented a webinar, “Dos and Don’ts of Safe Hoist Operation,” highlighting several best practices — including inspections. Ultimately, pre-shift hoist inspections keep an overhead lifting operation safe.

Why Pre-Shift Hoist Inspections Are Important

Pre-shift hoist inspections are important because hoists lift and lower heavy loads overhead. A hoist failure could potentially lead to the load falling from its suspended height, endangering the lives of personnel. A drop could also damage the lifted product, surrounding equipment, and facility structures.

Additionally, routinely verifying that a hoist is in safe, proper operating condition maximizes productivity. This confirmation reduces the risk of unplanned downtime and can extend the service life of the hoist.

Codes and Standards Call for Inspections

Multiple safety regulations and standards call for performing pre-shift hoist inspections. Sources include the Occupational Safety and Health Administration (OSHA), the American Society of Mechanical Engineers (ASME), and HMI. Applicable codes and standards are:

- OSHA-CFR 29 Part 1910.179 for overhead and gantry cranes (to which hoists attach) requires inspections of new and modified cranes and hoists. This federal regulation calls for a trained, qualified professional to perform inspections prior to use and at regular intervals.

- ASME B30.16 Overhead Hoists (Underhung) mandates that qualified, trained persons conduct regular inspections of powered underhung overhead hoists.

- ASME B30.21 Lever Hoists calls for regular inspections of manually powered lever hoists performed by qualified persons trained to do so.

- ASME B30.10 Hooks covers the visual inspection of hooks and slings used with hoists.

- HMI 100.24: Inspection and Maintenance Manual – Hoist provides information and suggestions for the inspection of overhead hoists.

- HMI 100.74: Inspection and Maintenance Manual – Lever Hoist offers recommendations and best practices for the inspection of manually-operated lever hoists.

What to Look for During Pre-Shift Hoist Inspections

There are several key areas to assess when performing a pre-shift hoist inspection, noted Matthew Frazier, Senior Manager of Engineering in New Product Development at HMI member Columbus McKinnon. Frazier presented this portion of the webinar.

Is an out-of-order or out-of-service tag attached to the hoist?

Is an out-of-order or out-of-service tag attached to the hoist?- Are the warning labels on the hoist present and intact?

- Do all motions properly match control device marks?

- Are the hook and latch working properly or are they damaged or deformed?

- Is the wire rope broken, kinked, or improperly wound?

- Is the load chain not worn, stretched, twisted, or distorted?

- Do the travel limits and hoist limit switches function properly?

- Are there any abrasions, wear, or weld splatters on the hoist that could inhibit its operation?

- Does the hoist make any unusual sounds in operation?

- Are there any obstructions in the surrounding area or travel path of either the operator or the hoist that could pose a hazard?

“The pre-shift hoist inspection should also include any guidelines or areas for assessment recommended by the hoist’s manufacturer,” Frazier added. “Those are in the equipment owner’s manual.”

Also, the operator should document the findings of every pre-shift hoist inspection, either on paper or electronically. The facility should retain those records to confirm they are being performed and to identify any areas of concern or patterns of wear.

“For operations needing more help with establishing a pre-shift hoist inspection process, HMI offers a comprehensive guide. HMI 100.24 Hoist Inspection and Maintenance Manual is a free download,” said Frazier. “The manual also includes helpful checklists that detail these key inspection areas.”

Learn More About Hoist Inspections

For those looking for a deep dive into pre-shift hoist inspections, HMI produced a webinar focused solely on this topic. In addition to hoist inspection publications, HMI offers a variety of other technical resources — including a comprehensive library of product guides; a hoist certification program; OSHA Alliance safety tip sheets, fact sheets and quick cards; multiple technical papers and more — via its website at www.MHI.org/hmi.