How To Determine When A Hoist’s Wire Rope Or Chain Should Be Replaced

As explained in the multiple free publications offered by the members of the Hoist Manufacturers Institute (HMI) that detail hoist inspection procedures, a variety of key components should be assessed when conducting one of the four primary types of hoist inspections: Initial, Pre-Shift, Frequent, and Periodic. While the proper functioning of all its components is critical to the hoist’s safe operation, the wire rope or chain used to lift and lower the load is often the part most prone to wear, damage, or deformation.

Key defects to look for on chains and wire ropes utilized in electric powered, air powered, and hand chain hoists are detailed in HMI 100.24: Inspection and Maintenance Manual – Hoist and for manually-operated lever hoists in HMI 100.74: Inspection and Maintenance Manual – Lever Hoist. The documents advise the following:

- Load chains should be assessed for any nicks, gouges, wear spots, indentations, shiny surfaces or dents, or any type of deformation or damage to the links. Suspected deformation or stretching can be confirmed by measuring a length of links and comparing the findings to the manufacturer’s recommended specifications included in the equipment owner’s manual. Additionally, lubrication on the load chain should be assessed. If any of these issues are detected, the hoist should be removed from service and its load chain should be replaced.

- Wire rope should be checked for distortion, kinking, unstranding, deposits of foreign material or dust, main strand displacement and core protrusion, corrosion, broken and cut wire strands, and birdcaging (when the strands that surround the wire rope core have separated from it due to shock loading). One approach to detecting hard-to-see damage is to protect the hand with a cotton glove or a thin cotton rag and run the material over the wire rope. Any snags or catch points in the material can indicate damage to the wire rope. If any of these conditions are found in the wire rope, the hoist should be immediately removed from service until its wire rope has been replaced.

- Load chain and wire rope reeving should be inspected to verify proper placement, no kinks or twists, and that the parts are not twisted together. If a problem is identified with the reeving, the hoist should be removed from service for repair.

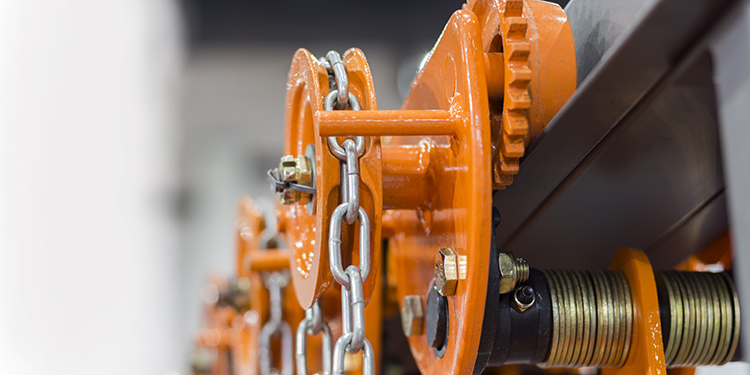

- Tensioning chains on lever hoists should be inspected for nicks, gouges, and any type of deformation or damage, as well as for lubrication. Should one or more of these issues be found, the lever hoist should be removed from service until its tensioning chain has been replaced.

HMI also recommends that all inspections adhere to the guidelines covered in the equipment owner’s manual provided by the hoist manufacturer. Best practice is to keep a copy of the hoist’s manual near the equipment, as it contains guidance on key points for inspection.

Seeking additional information on the safe operation of hoist systems? The members of the Hoist Manufacturers Institute (HMI) offer a variety of resources — including a comprehensive library of product guides; a hoist certification program; OSHA Alliance safety tip sheets, fact sheets and quick cards — via its website at www.MHI.org/hmi.