Overhead Handling Equipment Is Easy To Learn, Operate

This is the eleventh in a series of posts detailing 13 reasons why overhead lifting and handling technologies — specifically cranes, hoists, and monorails — can improve a manufacturing or distribution operation’s efficiency, productivity, safety, and sustainability. Read more in the free Overhead Alliance publication, “Expand Your Possibilities. Discover the Potential. Choose Overhead Lifting.”

With the proliferation of floor-based load transport vehicles, operations may overlook other handling options out of a lack of familiarity or awareness. Overhead handling equipment, for example, may not be the first solution that comes to mind. Further, that lack of exposure to cranes, monorails, and hoists may prevent a facility owner or operator may lead to misconceptions that the equipment can be difficult to use. In actuality, load movement and positioning with overhead handling equipment is easy to learn and operate.

That’s because cranes, monorails, and hoists operate under the direction of intuitive remote controls engineered for effortless use. Far simpler to learn and operate than ground-based material handling equipment for load lifting and positioning, remote controls for overhead handling solutions are straightforward and logical. This ensures precise, safe load handling that translates into both productivity and safety improvements.

Remote Controls Operate Overhead Handling Equipment

Young industry employees holding and working with remote control for operating crane

Operator directed overhead remote controls come in two primary types:

- Wireless remote controls, which utilize radio or infrared signals to relay function instructions to the system.

- Wired, push-button pendants (also called pendant stations) that relay commands to the equipment via direct connection.

Whether wired or wireless, overhead handling remote controls include up and down buttons for lifting and lowering. Arrows pointing in those two directions indicate which button to push. Controls also frequently incorporate directional buttons or joy sticks to direct the lateral movement of the load. Dials or levers control speed.

Intuitive Operation Makes Overhead Handling Equipment Easy to Learn

Compact enough for use with just one hand, remote controls are highly intuitive. This significantly minimizes operator training time as they familiarize themselves with the equipment. In fact, the learning curve to use overhead lifting systems is often considerably shorter than other types of load handling equipment.

Try Overhead Handling Equipment in Virtual Reality Game

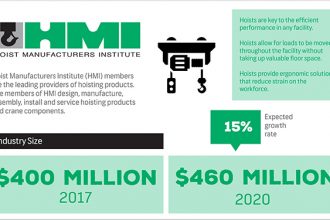

To demonstrate how easy it is to operate this equipment, MHI’s Overhead Alliance — comprised of the Crane Manufacturers Association of America (CMAA), the Hoist Manufacturers Institute (HMI), and the Monorail Manufacturers Association (MMA) — created the virtual reality (VR) “Crane Game.” The free game introduces novices to overhead lifting equipment and its operation.

Played while wearing an Oculus Rift VR headset, the game immerses the player in a realistic, 360-degree shop floor environment. There, he or she can safely operate the controls of a virtual overhead crane, overhead hoist, or jib crane. Players perform a series of load movement tasks while navigating through an obstacle course. Players also gain experience operating different types of lifting equipment within the game.

Learn More About Overhead Handling Equipment

Don’t let misperceptions about crane, monorail, and hoist operation prevent your operation from fully exploring its load handling options. Discover 13 different ways these technologies enhance manufacturing and distribution operations across a broad range of industries by downloading “Expand Your Possibilities. Discover the Potential. Choose Overhead Lifting.” This free guide comes from MHI’s Overhead Alliance (which includes the Crane Manufacturers Association of America (CMAA), the Hoist Manufacturers Institute (HMI), and the Monorail Manufacturers Association (MMA)).