Monorails 101: Get The Basics On This Load Lifting And Transport System

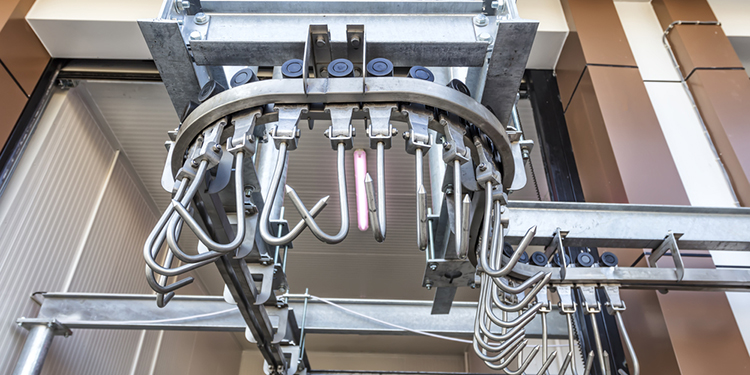

Typically utilized as an alternative to lift trucks or fixed, floor-mounted conveyor systems, monorails transport heavy, bulky materials throughout a facility or process, then position the loads. Monorails maximize a building’s vertical space by moving loads overhead — horizontally, vertically and laterally — on carriers (or trolleys) suspended from a continuous run of fixed, overhead track (or network of tracks) spanning almost any distance. Hand trolleys are powered manually; alternately, trolley movements can be powered by a pneumatic or electric tractor drive controlled by an operator using a wired pendant station or wireless controls. Fully automated systems are also available.

Most frequently deployed in manufacturing operations, monorails support production processes throughout facilities, including assembly, positioning, transport between workstations, staging of work-in-process, and movement to and from storage areas and loading docks. By relieving workers from the strains associated with lifting and pushing or pulling loads, monorails improve worker safety and ergonomics. Additionally, monorails free up floorspace, increase in performance and throughput, and provide highly efficient movement with precise positioning.

There are two different types of monorail track available:

- Patented Track – A continuous run of fixed, overhead track upon which carriers or trolleys travel, and are equipped with trolley hoists to lift, lower and suspend the load. Patented track monorails can also be equipped with interlocks, curves, and switches for flexible travel paths.

- Enclosed Track – A fully-contained track section fabricated to form an enclosure that acts as the running surface for the trolley wheels. In addition to allowing for smooth movement, enclosed track systems are ideal for keeping dirt and debris from the running surface. Enclosed track systems can also be equipped with curves and switches and can be provided in steel or aluminum profiles.

Looking for more information about how a monorail system might benefit your operation? The members of the Monorail Manufacturers Association (MMA) are the industry’s leading suppliers of overhead monorail systems. The group offers a variety of resources—including a product certification program, guidelines for specifying automated electrified monorail systems, recommended practices for workstation cranes and patented track systems, specifications for both patented track and enclosed track underhung crane and monorail systems, and more—via its website at www.MHI.org/MMA.