Not all crane manufacturers build their overhead handling products to the same standards. In the U.S., however, the most commonly used engineering and technical standards come from the members of the Crane Manufacturers Association of America (CMAA). CMAA specifications provide a common design standard for crane builders to use. This ensures that their products meet a set of minimum design standards for the intended application. There are other standards and specifications produced domestically and overseas. Still other standards cover highly specialized applications — such as nuclear facilities. This post explains why it’s important to buy overhead cranes built to CMAA specifications.

CMAA Specifications Developed by Crane Engineers

One reason to buy cranes built to CMAA specifications is that CMAA’s own Engineering Committee — currently comprised of 50 different members — writes, routinely updates, and approves them. Not only are they continuously kept up to date, but they also reference more than 150 other standards, including those published by the Occupational Safety and Health Administration (OSHA).

The standards cover the safe design, engineering, manufacturing, operation, and service of a broad range of overhead cranes, explained Bob Kotel, Chief Design Engineer at CMAA member G.W. Becker. As a former Vice President of CMAA’s Engineering Committee, Kotel has participated in the ongoing development and updating of CMAA specifications since 2016.

“Each member of CMAA’s Engineering Committee brings a wide range of experience across numerous industries to the specifications development process,” he said. “Further, CMAA’s Engineering Committee brings together engineers with expertise in mechanical, structural, and electrical design. Many of them have spent most of their careers in overhead material handling and have real world experience encountering just about every scenario within this industry.”

In addition to the diversity of the contributors and their collective overhead crane expertise, CMAA Engineering Committee members are also highly familiar with other types of material handling equipment, Kotel continued.

“This includes mining equipment, conveyor systems, below-the-hook lifting devices, transfer cars, and more. That diversity of experience helps improve CMAA’s standards,” he said.

Multiple Crane Duty Classes Make Selection More Precise

A crane designed to CMAA specifications often proves to be a more cost-effective solution. That’s because CMAA divides cranes into six different classes — A through F. This helps users and manufacturers more precisely determine their duty cycle. Duty cycles are determined based on the anticipated frequency of crane use, the type of load, and the average weight of the loads handled.

“By dividing these classes into six different degrees of usage, CMAA recognizes that there are applications that require cranes to withstand continuous, severe duty applications, as well as others used more intermittently and in less demanding applications,” explained Kotel.

Six Different Crane Duty Classes

The six different classes allow a buyer to match the optimal crane to an application’s unique requirements—that is, purchase the equipment that ensures a full return on investment. They also enable a more accurate comparison when evaluating different crane equipment proposals from different suppliers.

They include:

- Class A – Standby or infrequent usage where precise handling of equipment at slow speeds with long idle periods between lifts.

- Class B – Light service at slow speeds, with up to five lifts per hour up to maximum rated capacity.

- Class C – Moderate service, including handling an average of 50 percent of the rated capacity up to 10 times per hour.

- Class D – Heavy service, where the crane handles loads of 50 percent of the rated capacity constantly.

- Class E – Severe service, where the crane makes 20 or more lifts per hour at or near its rated capacity.

- Class F – Continuous severe service, including cranes that handle loads approaching the maximum rated capacity non-stop under extreme conditions.

“When an end user purchases a crane built to CMAA specifications, they can be assured that they are getting a piece of equipment that will perform as needed for the intended duty cycle of their operation,” Kotel added. “The crane will also last for the lifetime they are looking to achieve with their equipment.”

Five CMAA Technical Specifications and Standards Available

CMAA currently publishes and continuously updates five separate standards for safe overhead crane design, engineering, manufacturing, operation, and service. They include:

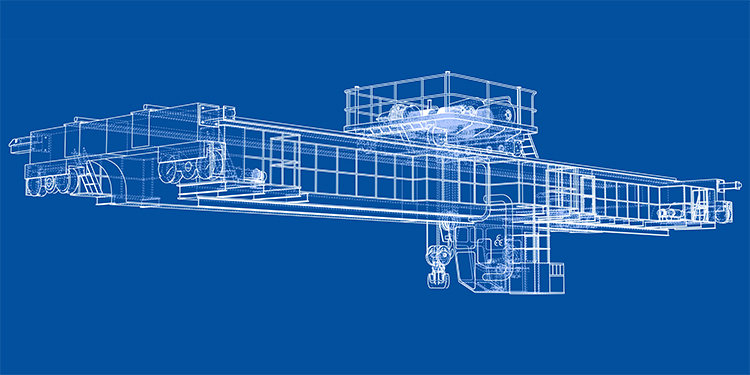

- CMAA Specification 70: Specifications for Top Running Bridge & Gantry Type Multiple Girder Electric Overhead Traveling Cranes

- CMAA Specification 74: Specifications for Top Running & Under Running Single Girder Electric Traveling Cranes Utilizing Under Running Trolley Hoist

- CMAA Specification 78: Standards and Guidelines for Professional Services Performed on Overhead and Traveling Cranes and Associated Hoisting Equipment

- CMAA Specification 79: Crane Operator’s Manual

- CMAA Specification 80: Below-the-Hook Lifting Device Operator’s Manual

Learn More About CMAA

CMAA members represent the industry’s leading suppliers of overhead crane systems. They design, manufacture, assemble, install and service overhead cranes and components. CMAA members, with the combined experience of more than 30,000 crane installations in North America in the last decade, are committed to providing products which focus on safety and innovation. In addition to its engineering specifications, the organization offers a variety of other resources — including buyers’ guides, OSHA Alliance safety tip and fact sheets, inspection and maintenance checklists, safety seminars and more — via its website at www.MHI.org/CMAA.

Want to purchase copies of the five CMAA Specifications? Visit the full library of technical specifications.