Updated CMAA Specification 74 Strengthens Safety and Design for Single-Girder Cranes

The Crane Manufacturers Association of America (CMAA) has released the 2025 revision of Specification No. 74. The document is the definitive design reference for top-running and under-running single-girder electric traveling cranes using under-running trolley hoists. The updates to CMAA Specification 74 reflect today’s advances in materials, controls, and load-handling technologies. It gives engineers, specifiers, and crane owners a clear, current roadmap for designing, manufacturing, and maintaining single-girder cranes. Use of the specification ensures that this type of overhead lifting equipment meets expectations for safety, reliability, and performance.

Why Was CMAA Specification 74 Revised?

CMAA revises its specifications roughly every five years to reflect new technologies and industry best practices. The 2025 edition incorporates lessons from the field, aligning design guidance with today’s expectations for automated systems, digital controls, and improved safety margins.

CMAA revises its specifications roughly every five years to reflect new technologies and industry best practices. The 2025 edition incorporates lessons from the field, aligning design guidance with today’s expectations for automated systems, digital controls, and improved safety margins.

This revision also brings CMAA Specification 74 in closer alignment with related publications from the American National Standards Institute (ANSI), the American Society of Mechanical Engineers (ASME), and the Occupational Safety and Health Administration (OSHA). CMAA’s objective is to provide greater clarity, consistency, and uniformity across crane design, fabrication, and operation.

Highlighting CMAA Specification 74’s Key Changes

The updated CMAA Specification 74 extensive updates across structural, mechanical, and electrical sections. Revisions include:

Structural Modifications.

The revision incorporates clarified guidance on allowable stress, deflection limits, torsion, and wheel load distribution. It also refines runway interface design criteria for both top-running and under-running configurations.

Mechanical and Component Changes.

New details define end-truck geometry, bearing stress limits, and trolley hoist load distribution. The revisions also tie component sizing more closely to material strength and fatigue data for modern steels.

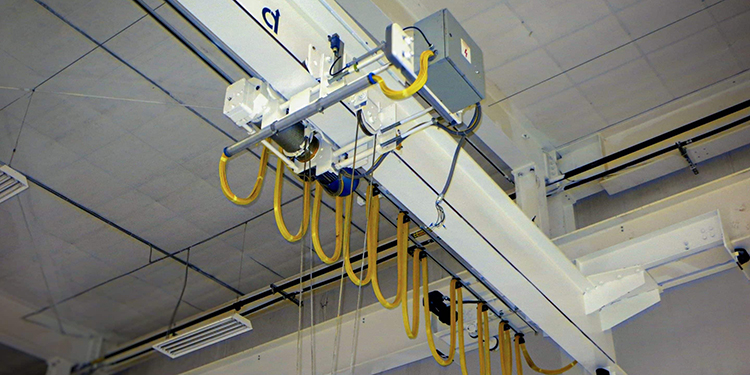

Electrical and Control System Enhancements.

References to the latest wiring practices and control technologies include recommendations for variable-frequency drives (VFDs), anti-sway systems, and programmable logic controller (PLC)-based motion control.

Safety and Inspection Clarifications.

Expanded commentary provides inspection intervals, maintenance record guidance, and enhanced labeling and guarding requirements. These updates strengthen alignment with OSHA regulations and modern risk management practices.

Glossary Updated.

To improve clarity across engineering, manufacturing, and inspection activities, the revision added a new definition.

-

- Diaphragm – A plate or partition between opposite parts of a member, serving a definite purpose in the structural design of the member and can be either full depth or short depth. Full depth diaphragms may stop short of tension flange except at the ends of structural box members. Short depth diaphragms are typically located in the compression stress zone of the web and are used for web buckling stability or to support bridge/trolley rail, or both.

Commentary and Interpretive Guidance Expanded.

Additional commentary helps users interpret design formulas, apply duty classes, and assess expected service life. These notes give engineers more flexibility while maintaining standardization and safety.

In total, the updates reflect CMAA’s ongoing effort to modernize its specifications to support evolving technologies. The revisions account for the latest developments in digital controls, performance monitoring, and lifecycle design principles.

Where to Access the Updated Specification

CMAA Specification 74-2025 is accessible as a download www.mhi.org/cmaa. CMAA’s technical committee welcomes interpretation requests and technical inquiries via its contact portal.

Learn More About CMAA

CMAA members represent the industry’s leading suppliers of overhead crane systems. They design, manufacture, assemble, install and service overhead cranes and components. CMAA members, with the combined experience of more than 30,000 crane installations in North America in the last decade, are committed to providing products which focus on safety and innovation.

In addition to its engineering specifications, the organization offers a variety of other resources. These include buyers’ guides, OSHA Alliance safety tip and fact sheets, inspection and maintenance checklists, safety seminars, Learn more via CMAA’s website at www.MHI.org/CMAA.