5 Signs That A Workstation Crane Needs To Be Replaced

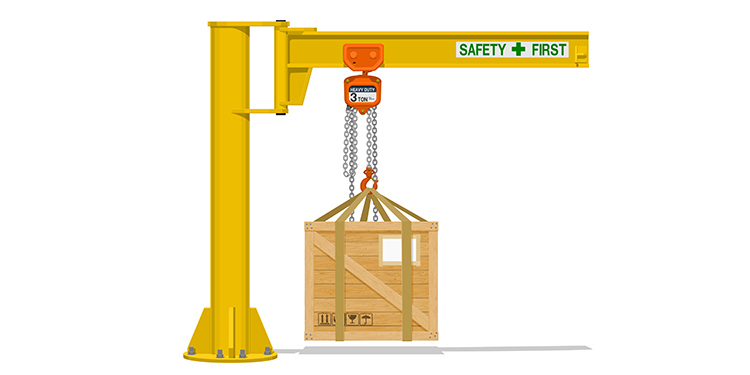

Typically designed to loads ranging from 150 to 4,000 pounds, workstation cranes are dedicated to a specific area or location and are equipped with a load handling device, such as a hoist, that suspends the load. Offered in jib, bridge, ...

The “Dos And Don’ts” Of Workstation Cranes

Workstation cranes — offered in jib, bridge, and gantry styles — are often deployed in manufacturing and assembly operations where operators must lift, handle, and move heavy objects as part of a work process. Generally handling loads ranging from 150 ...

Crane Selection Guidelines: How To Pick The Right Solution For ...

Overhead single and double girder crane equipment is engineered to lift, lower and move large, heavy and bulky loads horizontally through a facility’s overhead space. The crane’s movement (and load travel) is controlled by an operator through a rectangular area ...

Work Cell Layouts: Key Considerations When Implementing A Workstation Crane

Offered in four styles — jib, monorail, bridge, and gantry — workstation cranes are installed in work cells to help operators lift, handle, transport, and position heavy objects within assembly and manufacturing operations. Yet, to ensure proper ergonomics when using ...

Workstation Cranes 101: An Overview Of This Ergonomic Solution

Frequently found in manufacturing and assembly operations where workers need to lift, handle, and move heavy objects to perform various processes upon them, workstation cranes generally handle loads from 150 to 4,000 pounds. Dedicated to a specific location or area, ...