ANSI ACE 35-2026 Updates Improve Clarity, Safety, and Collaboration in Crane Electrification

A Guest Post from the Members of the Automation, Controls, And Electrification Association (ACE).

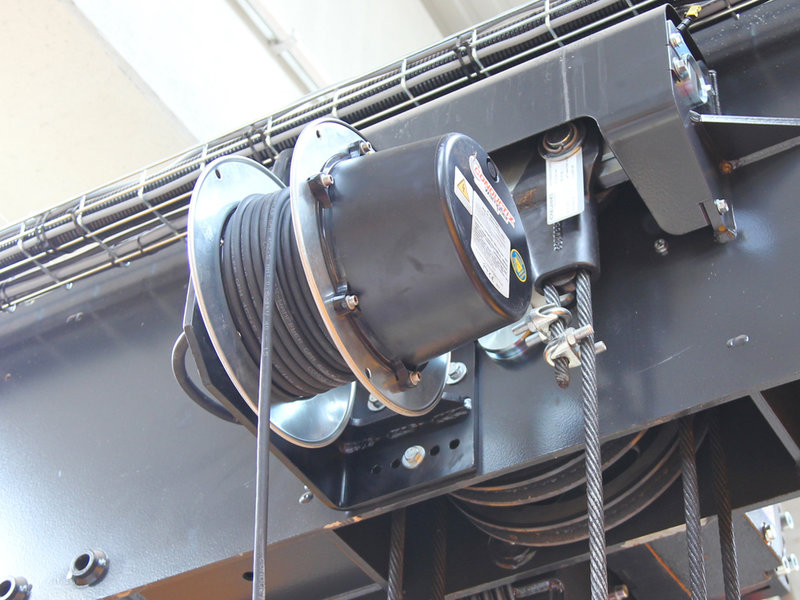

The electrification systems that power overhead traveling cranes may not be the most visible part of a crane design, but they are among the most critical. Conductor bars, festoon systems, cable reels, and slip rings are key components that safely deliver power to moving equipment. Used for decades, these systems require careful design and application. To help manufacturers, installers, and end users responsible for overhead crane electrification, American National Standards Institute ANSI ACE 35 has been updated and reissued.

Formerly known as ECMA 35, the updates reflect both the evolution of the industry and the expanded scope of the organization overseeing the standard. Previously, the MHI industry group responsible for its content and publication was known as the Electrification and Controls Manufacturers Association (ECMA). With ECMA’s name change to the Automation, Controls, and Electrification Association (ACE) in 2023, the standard is now ANSI ACE 35-2026: Electrification Systems for Electric Overhead Traveling Cranes.

Why Update ANSI ACE 35?

Like all ANSI-backed standards, ACE 35 follows a regular review cycle to ensure it remains current and relevant. According to Wayne Goodspeed, Director of Project Management at ACE member Magnetek Products, a division of Columbus McKinnon Corporation, the update was as much about stewardship as it was about change. Goodspeed served on the ACE engineering committee responsible for updating ANSI ACE 35.

“Most standards are refreshed every five to seven years,” said Goodspeed, who noted that the previous edition appeared in 2018. “In this case, the rebranding from ECMA to ACE was another reason for the refresh.”

Radical technological shifts, however, did not drive the updates. Instead, the committee focused on refining how the standard communicates expectations and responsibilities.

“This is particularly important as crane systems and jobsite environments continue to grow more complex,” added Goodspeed.

Clarifying Language, Responsibilities, and Engineering Expectations

One of the most significant themes of ANSI ACE 35 is clarity—particularly around what the standard requires versus what it recommends.

One of the most significant themes of ANSI ACE 35 is clarity—particularly around what the standard requires versus what it recommends.

“It’s really a further development of the previous standard,” Goodspeed explained. “It’s not a complete rewrite. We cleaned up terminology to make it clearer what’s mandatory and what’s advisory. We also strengthened some of the system-level design accountabilities.”

Those clarifications extend to technical areas that could be misinterpreted or inconsistently applied in the field. For example, the updated standard refines calculations for voltage drop and load modeling for conductor bar and festoon systems. The intent was to make the guidance easier to interpret and apply without changing the underlying engineering principles.

“The calculation itself didn’t fundamentally change,” Goodspeed said. “It just needed to be refreshed and clarified so people better understand how to apply it.”

The standard also more explicitly recognizes engineered subsystems—including cable reels and slip rings—as integral parts of electrification systems, rather than treating them as secondary components. This systems-level perspective more accurately reflects the design and operation of modern cranes and their electrification systems.

Reinforcing Collaboration Across the Supply Chain

Another important evolution in ANSI ACE 35 is how it addresses responsibility sharing between crane manufacturers and electrification product suppliers.

Ben Hiebenthal, Mechanical Engineer III and Platform Lead for Rotary Motion Products at ACE member Conductix-Wampfler, noted that previous language sometimes implied that one party should carry most of the burden when specifying electrification systems.

“We clarified that it’s really a collaboration,” said Hiebenthal, who worked alongside Goodspeed to coordinate the standard’s updates. “The crane builder usually understands the application and environment, while the product manufacturer is the expert on the electrification equipment. The standard now better reflects that information has to flow both ways.”

This clarification helps address real-world scenarios where application-specific details can significantly affect product selection and system performance. These include travel speed, duty cycle, environmental exposure, or the presence of sensitive equipment like variable frequency drives.

The updated language also acknowledges that general recommendations do not always apply universally, continued Hiebenthal.

“There are cases where the general rule of thumb works 90% of the time, but 10% of the time it doesn’t,” he explained. “Those situations are very application-specific, and that’s where communication between the user and the supplier becomes critical.”

ANSI ACE 35 Improves Safety by Reducing Ambiguity

Rather than adding new layers of requirements, the engineering committee focused on improving safety by eliminating confusion.

“The update improves safety by not adding complexity,” Goodspeed said. “By cleaning up ambiguities, it makes certain safety-critical requirements more enforceable because the guidelines are clearer.”

ANSI ACE 35 continues to emphasize that it is a guideline, not a replacement for local, state, or national codes. Users are still responsible for complying with applicable regulations and following manufacturer instructions. However, the standard provides a clearer baseline for key considerations when designing and applying crane electrification systems.

The standard also aligns more deliberately with related industry documents, such as overhead crane specifications published by the Crane Manufacturers Association of America (CMAA). This helps users understand where general guidance ends and more prescriptive requirements begin.

A Practical, Accessible Tool for the Industry

At just 18 pages, ANSI ACE 35 is intentionally concise. Its purpose is not to dictate every design decision, but to give users—especially those newer to crane electrification—a clear framework for making informed choices.

“If I had to lump the whole standard into one purpose,” Hiebenthal said, “it’s to help someone decide, based on their application, what type of electrification product fits best and how to implement it safely.”

Goodspeed echoed that sentiment, emphasizing the standard’s role as a starting point.

“It’s a collection of information that helps the user say, ‘This is what should be on my equipment,’” he said. “From there, they can work with their suppliers, follow local codes, and take it to the next level.”

Learn More About ACE

Automation, Controls, and Electrification (ACE) members are the Industry’s leading suppliers of electrification and controlling devices. They supply solutions worldwide and in virtually every major manufacturing and distribution sector. To learn more about ACE and the solutions and resources it offers, visit mhi.org/ace.