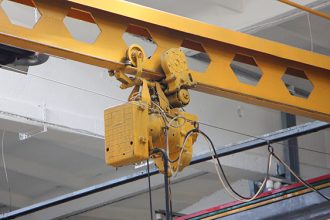

Don’t Ignore These Overhead Crane Safety Basics

Overhead crane equipment lifts, lowers, and transports large, heavy, and bulky loads overhead through a facility. As they transfer their payloads horizontally, they cranes also boost handling throughput and optimize facility space. Operations adding an overhead crane — or those with one or more in use — have responsibilities critical to the safe operation of this equipment. For this reason, the Crane Manufacturers Association of America (CMAA) publishes multiple specifications and technical papers for the design, operation and service of cranes. To enhance equipment reliability and reduce the risk of injury for workers as they operate the crane or work in proximity to it, don’t ignore these overhead crane safety basics.

Overhead Crane Safety Best Practices

Match the Crane Duty Cycle to the Application

It is important to verify that the CMAA duty cycle (frequency of use, type of load, and average load weight) of the crane matches the application when specifying/purchasing the equipment. While it may cost more, a crane that is properly sized to meet the task at hand will last longer. It will also be less likely to require early replacement of motors, brakes, electrical components, and other key mechanisms.

Read the Owner’s Manual

Developed by the crane’s manufacturer and provided upon installation, these documents contain critical information. They detail specifications, dimensions, operation instructions, inspection criteria, parts lists, and other key overhead crane safety guidance.

Follow OSHA Guidelines

The Occupational Safety and Health Administration (OSHA) requires facility operators to provide their employees with equipment that is both safe and operates property. This includes overhead cranes.

Conduct Regular Inspections

Inspect every crane prior to the start of each shift before operation. More detailed inspections should also occur at frequent and periodic intervals. Additionally, cranes used in harsh environments and/or with a higher duty cycle will require frequent and periodic inspections to be performed more often.

Perform Regular Preventive Maintenance

To ensure overhead crane safety and long service life, perform regular preventive maintenance as specified by the manufacturer. If it is necessary to outsource preventive maintenance and repairs, engage independent crane service professionals with experience on the specific equipment.

Allow Only Trained Personnel to Operate Cranes

Only those employees who complete training on the proper use of the overhead crane equipment should be allowed to use it. Training should be provided by someone experienced with the equipment.

Follow All Manufacturer’s Safe Operation Recommendations

Require all crane operators to follow manufacturer specified safety precautions when operating the equipment. This includes:

- Not allowing an untrained operator to rig a load.

- Not attempting to lift a load that exceeds the capacity rating of the crane.

- Not using the crane more frequently than its duty cycle specifies.

- Not slamming the bridge or trolleys into the end stops, which can damage the equipment.

- Not using the crane for any purpose outside its specified function.

Looking for More Information on Overhead Cranes?

Available to answer any questions, CMAA members represent the industry’s leading suppliers of overhead crane systems. With the combined experience of more than 30,000 crane installations in North America over the last decade, CMAA members are committed to providing products focused on both safety and innovation. Additionally, the group offers a variety of resources — including buyers’ guides, engineering specifications, OSHA Alliance safety tip and fact sheets, inspection and maintenance checklists, safety seminars and more — via its website at www.MHI.org/CMAA.