How Patented Track And Enclosed Track Enable Design Flexibility

Used to lift, handle, transport, and position heavy objects within assembly and manufacturing operations, workstation bridge cranes and monorails are frequently deployed in manufacturing and assembly operations to assist workers. At the heart of each of these systems are the tracks upon which the trolleys bearing a load travel — patented track and enclosed track. Each track style offers a variety of versatile options and load handling characteristics, enabling a facility owner to create the optimal overhead handling system (permanent, temporary, or modular) that precisely meets process needs. Here, a look at each type of track and the features that enhance system flexibility.

Patented Track Systems

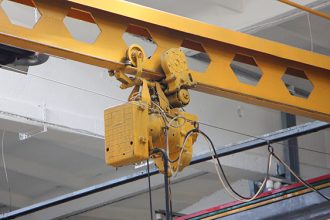

Used to lift and transport loads weighing up to 40 tons, underrunning patented track cranes and monorails are constructed from hard alloy steel in an inverted-T profile. The high strength and low deadweight of this profile permits long spans of track to be constructed with minimum load transfer to the support structure. Loads are moved automatically with pneumatic or electric powered trolleys, or manually with a push from a worker. Either way, because the track running surface is machined to precise tolerances, trolleys travel on it smoothly and with minimal wear.

The precise, machined tolerances of the bottom flange also ensure smooth load transitions at connection points where track components are bolted together. Additionally, to match specific application needs, modular patented track sections may be specified in a variety of profiles, as well as in curves, interlocks, switches and more.

Patented track systems can be provided with a freestanding structure to accommodate buildings with high ceilings or multiple overhead obstructions. Conversely, they can also be suspended from the ceiling — eliminating obstructions to floor traffic. When hung from the ceiling, patented tracks are installed with hanger rods made of high tensile steel for strength and durability. Threaded hanger rods permit height adjustments to avoid obstructions, as well as create elevation ascents and descents.

Lastly, when a complex monorail path running throughout a facility is created with patented track — or to enable a load to be transferred to and from adjacent cranes, between bays, or into other buildings — a variety of interlocks, track switches, turntables and other devices may be utilized within the design.

Enclosed Track Systems

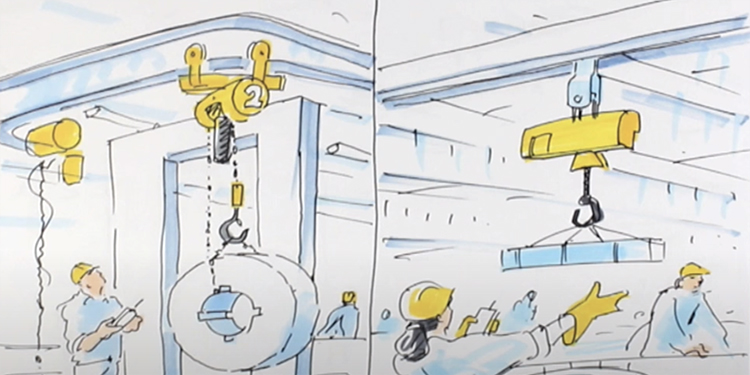

Capable of lifting and transporting loads weighing up to 3 tons, enclosed track workstation cranes and monorails feature fully contained track sections fabricated to form an enclosure that acts as the running surface for the trolley wheels. Not only does this provide a smooth running surface, but the enclosed design also protects the track from dirt and debris that might impede the rolling of the trolley wheels.

Depending on the application, a choice of track materials is offered: high-strength, low-deadweight rolled steel, or extruded aluminum. Further, track sections are formed in a variety of profiles, curves, interlocks, switches, and more, allowing the track to precisely match the needs of the application. Modular, the sections are bolted together, allowing fast installation and easy future expansion or reconfiguration as production needs change.

Enclosed track systems can be suspended from a ceiling or — should the ceiling be too high or overhead obstructions are present — they can be supported by a freestanding structure. To accommodate differing ceiling elevations and other impediments, as well as to create inclines and declines, adjustable height hangers clamp or bolt on to the enclosed track, keeping it level while navigating the obstacles.

Finally, when enclosed track is used to create a complex monorail path throughout a facility (or to enable a load to be diverted to and from a work cell), a variety of interlocks, track switches, turntables and other devices may be specified.

Want to learn more ways workstation bridge cranes and monorails can help your workers be both safer and more productive? The members of the Monorail Manufacturers Association (MMA) are the industry’s leading suppliers of workstation crane systems. The group offers a variety of resources—including a product certification program, recommended practices for workstation cranes and patented track systems, and more—via its website at www.MHI.org/MMA.