How Overhead Lifting Equipment Enhances Workplace Safety

This article previously appeared in the February 2023 issue of Workplace Material Handling & Safety magazine.

Contributed by the members of the Overhead Alliance, which is comprised of the Crane Manufacturers Association of America (CMAA), the Hoist Manufacturers Institute (HMI), and the Monorail Manufacturers Association (MMA).

Employee safety is a top priority in every operation, particularly with current workforce shortages. It’s become more important than ever to keep the personnel safe on the job in manufacturing, warehousing, and distribution operations.

Yet many tasks in these facilities involve manual lifting, pushing, or pulling to transport loads. Indeed, according to Liberty Mutual Insurance’s 2022 Workplace Safety Index, the leading cause of serious, debilitating workplace injuries — those that cause employees to miss five or more days of work — is overexertion related to manually handling loads. The report notes that these injuries cost employers $12.63 billion every year in workers compensation, medical, and lost-wage expenses.

To reduce the risks of such injuries — and the associated costs — there are a variety of overhead handling technologies available to replace manual labor and floor-based vehicles for lifting, lowering, transporting, and positioning loads. These solutions include:

- Overhead Cranes lift, lower, and move large, heavy, and bulky loads through the overhead space in a facility. Built with high lifting capacities, cranes support multi-directional load movement in a rectangular area, transporting a load side to side, backwards, and forwards. An operator controls their function manually or with a wired pendant or wireless controller. When used indoors, cranes support manufacturing processes (such as staging and assembly for work-in-process), warehousing storage, and loading and unloading activities. Outside cranes handle loading and unloading in yards, at shipping ports, and at railroad depots.

- Monorails transport heavy, bulky materials throughout a facility or process, then position the loads. Monorails maximize a building’s vertical space by moving loads overhead — horizontally, vertically, and laterally — on carriers (trolleys) suspended from a continuous run of fixed, overhead track spanning almost any distance. Powered manually or by an operator using a wired pendant station or wireless controls, monorails are most often found in manufacturing applications.

- Workstation Cranes help workers lift, handle, and move heavy objects to perform work on them. Dedicated to specific work areas, workstation cranes incorporate a vertical lifting device that suspends the load during manipulation, travel, and placement.

- Hoists work in conjunction with overhead cranes, monorails, and workstation cranes as the key component that makes the vertical lifting and lowering of loads possible. Hoists connect to cranes via a trolley that travels the length of the crane bridge; attach to individual monorail carriers; or hang from the end of a cantilevered bridge or from a runway in a workstation crane application.

How Overhead Lifting Solutions Enhance Employee Safety

Applying a combination of these overhead lifting solutions in a manufacturing, warehousing, or distribution operation safeguards employees in several ways.

First, because overhead lifting technologies handle the heavy lifting, they eliminate the ergonomic strains and exertions associated with manually lifting, pushing, or pulling heavy loads. Solutions exist for loads from 50 pounds to over 100 tons or more, preventing physical injuries.

Second, overhead lifting systems reduce the need for floor-based load movement technologies. Restricted to a specific zone within an operation and operated solely in a facility’s overhead space, these solutions significantly reduce employee exposure to potential accidents caused by such vehicles navigating loads through tight spaces.

Third, overhead lifting solutions move along predictable travel paths at controlled speeds. To maximize productivity and reduce the risk of collisions, overhead lifting systems navigate in a predictable path at a steady pace. Integrated safety devices, such as audible alarms and flashing lights, alert workers to the overhead system’s operation for additional safety.

Fourth, a variety of devices further enhance and ensure the safe operation of overhead lifting technologies. These include smart crane technologies that intuitively predict a problem, such as excessive load sway, collisions, off-center lifts, or snags; sway control technologies that predict and counteract the natural pendulum effect that occurs when starting or stopping load motion; limit switches, digital lasers, and encoders that restrict crane travel to specific facility zones; collision avoidance systems; and detection systems that alert an operator to an off-center or snagged load.

Overhead Lifting Resources for Safer Operations

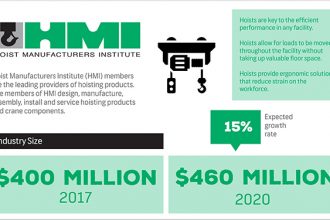

The Crane Manufacturers Association of America (CMAA), the Hoist Manufacturers Institute (HMI), and the Monorail Manufacturers Association (MMA) each produce engineering and technical standards specifications for the safe design, engineering, manufacturing, operation, and service of overhead lifting equipment. The standards cover a broad range of crane, hoist, monorail, and workstation crane types. Produced under American National Standards Institute (ANSI) guidelines, all are recognized internationally as the leading resource for the safe construction and utilization of overhead lifting systems.

CMAA, HMI, and MMA also publish a comprehensive collection of publications for the selection of the optimal overhead lifting equipment for a given application. These product and buyer’s guides help with the evaluation and specification of the best solution for the load’s characteristics, the operating environment, facility limitations, frequency of use, service duty, desired handling speed, and more.

The three associations also offer guidelines and checklists for the proper, routine maintenance and safety inspections of the equipment. These include free pre-inspection checklists for operators to follow at the start of each shift with details about each area to examine. There are also guidelines for conducting more in-depth inspections on frequent or periodic timeframes to verify that the equipment remains in proper, safe working order. The guidelines include instruction for how to handle any issues uncovered during these assessments to ensure the safest operation.

To further enhance the safe use of overhead lifting equipment, CMAA, HMI, and MMA produce operators’ manuals, safety tip sheets, fact sheets, quick cards, webinars, and other educational resources for owners and users. Because training is a key component of a safe facility, the three associations provide extensive materials to support comprehensive instruction of overhead equipment operators.

When considering ways to safeguard employees, look to overhead lifting equipment to provide an ergonomic and predictable means to transport, lift, lower, and position loads within a facility. The members of CMAA, HMI, and MMA are available to offer additional guidance and input on ways these technologies enhance the safety and productivity of an operation.

About the Author

The Overhead Alliance — a joint collaboration of the Crane Manufacturers Association of America (CMAA), the Hoist Manufacturers Institute (HMI), and the Monorail Manufacturers Association (MMA) — provides information about the benefits of overhead lifting in industrial applications. It also produces educational videos, sponsors safety-focused educational seminars and webinars, and shares details about the latest technological developments in the field. Additionally, the group works with the Occupational Safety & Health Administration (OSHA) as the Crane, Hoist, and Monorail (CHM) Alliance Program Ambassador. Through this partnership, the two organizations provide information, guidance and access to training resources that help protect the health and safety of worker using hoists, cranes, and monorails.